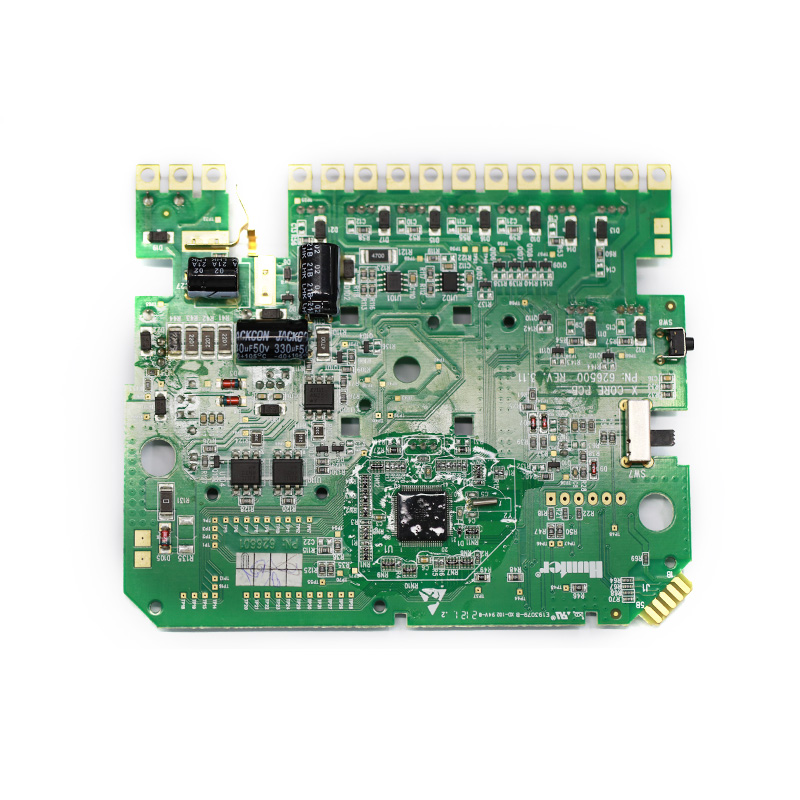

Quais são os diferentes tipos de placas de circuitos impressos e as suas utilizações?

Printed circuit boards (PCB) are essential components found in almost all electronic devices. They are the backbone of modern technology, providing a means to connect and organize electronic components, allowing them to function smoothly. There are various types of printed circuit boards, each with its unique design and purpose. In this article, we will explore the different types of PCB and their uses.

Single-sided PCB:

A single-sided PCB is the most basic type of circuit board and is the most commonly used. As the name suggests, this type of board only has one layer of conductive material (usually copper) on one side. Passive components such as resistors, capacitors, and diodes are placed on the top side of the board, while all the traces (electrical pathways) and solder pads are on the bottom side. The use of single-sided PCB is typically limited to simple, low-cost devices such as calculators, toys, and LED lights.

Double-sided PCB:

A double-sided PCB has conductive material on both sides of the board, allowing for more complex circuit designs. This type of board is commonly used for more advanced electronic devices, such as printers, mobile phones, and home appliances. The components are mounted on both sides of the board, and the traces are routed through vias (small holes drilled in the board) to connect the top and bottom layers. Double-sided PCB are relatively affordable and more versatile than single-sided ones.

Multi-layer PCB:

As the name implies, a multi-layer PCB has multiple layers of conductive material and insulating material, sandwiched together to form a single board. This type of board is typically used for advanced electronic devices, where space is limited, and high functionality is required. Multi-layer PCB are commonly used in computers, routers, and other complex devices. They can have anywhere from 4 to 20+ layers, depending on the complexity of the circuit layout.

Rigid PCB:

A rigid PCB is the most common type of PCB and is made of rigid materials such as fiberglass or epoxy resin. It is stiff and cannot be bent, making it suitable for most electronic devices. Rigid PCB are available in single, double, and multi-layer configurations.

Flexible PCB:

A flexible PCB, also known as a flex PCB, is made of flexible materials such as polyimide or polyester. These materials allow the board to bend or twist, making them ideal for electronic devices that require a custom shape. Flex PCB are commonly used in consumer electronics, such as smartphones, tablets, and wearables. They are also used in aerospace, military, and medical applications, where weight, size, and durability are crucial factors.

Rigid-Flex PCB:

A rigid-flex PCB is a combination of rigid and flexible PCB, providing both advantages within a single board. This type of board is designed to have a rigid section for components that require stability and a flexible section for moving or bending parts. These boards are commonly used in smartphones, cameras, and other electronic devices with moving parts.

High-Frequency PCB:

High-frequency PCB are designed to handle signals in the high-frequency range, typically above 1GHz. They are made of special materials, such as PTFE (polytetrafluoroethylene) or ceramic, which have low dielectric loss and can maintain a stable signal. High-frequency PCB are used in applications such as satellite communications, radar systems, and medical equipment.

Metal-Core PCB:

A metal-core PCB has a metal layer as the base, usually aluminum, with a layer of insulating material on top and a layer of copper on the bottom. This type of board is commonly used for high-power applications, as the metal layer acts as a heat sink, dissipating heat generated by the components. Metal-core PCB are used in LED lighting, power supplies, and automotive electronics.

High-Density Interconnect (HDI) PCB:

HDI PCB are designed to have a high-density of components in a compact space. They use microvias, blind vias, and buried vias to connect the layers, allowing for a more complex and compact circuit design. HDI PCB are used in smartphones, tablets, laptops, and other compact electronic devices.

Integrated Circuit (IC) Substrate PCB:

IC substrate PCB are used to mount the integrated circuits (ICs) of electronic devices. They are typically made of ceramic or glass material, and the ICs are mounted on top using wire bonding or flip-chip technology. IC substrate PCB are used in computers, telecommunications, and other electronic devices that require advanced microchips.

In conclusion, printed circuit boards come in various shapes, sizes, and configurations to suit different electronic devices. Each type of PCB has its unique design and purpose, making them essential components of modern technology. As technology continues to evolve, so will the design and use of printed circuit boards, making them an integral part of our daily lives.