Innovative PCB Assembly Solutions for Electronics Manufacturing by MTI

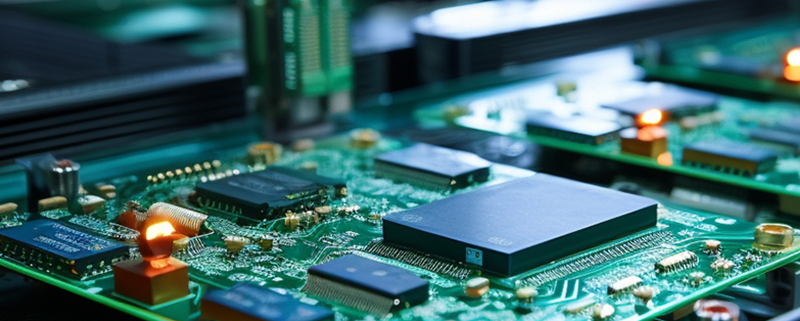

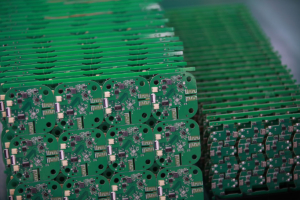

At MTI, a leading PCB assembly manufacturer, we specialize in delivering innovative PCB assembly solutions that cater to the dynamic needs of the electronics manufacturing industry. As the backbone of modern electronic devices, printed circuit boards (PCBs) require precise assembly processes that ensure reliability, performance, and scalability. In this article, we explore the advanced PCB assembly solutions offered by MTI and how they contribute to the success of electronics manufacturers worldwide.

Understanding the Importance of PCB Assembly in Electronics Manufacturing

The Role of PCB Assembly

PCB assembly is a critical process in electronics manufacturing that involves mounting electronic components onto a PCB to create functional circuits. The quality and precision of this assembly directly impact the performance, durability, and reliability of the final electronic product. At MTI, we recognize the importance of flawless PCB assembly, and we are committed to delivering solutions that meet the highest industry standards.

Challenges in PCB Assembly

The PCB assembly process presents several challenges, including the need for miniaturization, high-density component placement, and the integration of advanced technologies. Electronics manufacturers must also address issues such as heat dissipation, signal integrity, and product testing to ensure optimal performance. MTI’s innovative PCB assembly solutions are designed to overcome these challenges, enabling manufacturers to produce high-quality electronic devices with confidence.

MTI’s Advanced PCB Assembly Solutions

Surface Mount Technology (SMT)

Precision and Efficiency

Surface Mount Technology (SMT) is a widely used method in PCB assembly that involves placing components directly onto the surface of the PCB. MTI utilizes state-of-the-art SMT equipment to achieve high precision and efficiency in component placement. Our advanced SMT lines are capable of handling a wide range of component sizes, including micro-sized components, ensuring that even the most complex PCBs are assembled with accuracy and speed.

High-Density Assembly

With the trend towards miniaturization in electronics, high-density assembly has become increasingly important. MTI’s SMT capabilities allow for the assembly of densely packed PCBs with minimal spacing between components, optimizing the use of available space. This is particularly beneficial for manufacturers producing compact electronic devices such as smartphones, wearables, and IoT devices.

Through-Hole Technology (THT)

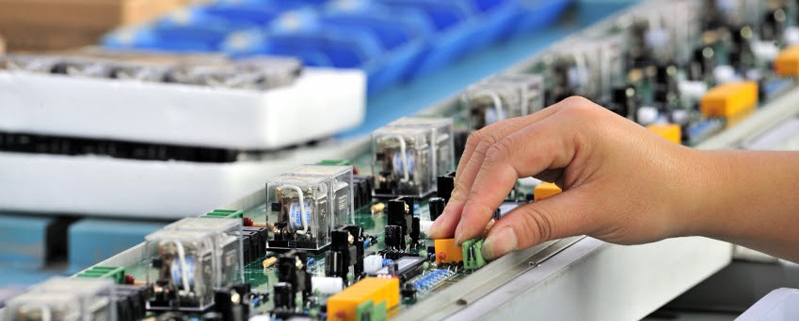

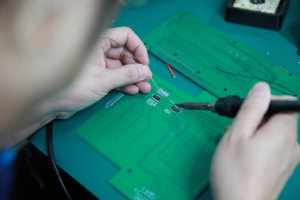

Reliable Connections for Power and Durability

Through-Hole Technology (THT) is another essential PCB assembly method, particularly for components that require strong mechanical bonds and reliable electrical connections. MTI’s THT assembly solutions are ideal for power-intensive applications and products that demand durability, such as industrial equipment and automotive electronics. Our expertise in THT ensures that all components are securely soldered and capable of withstanding harsh operating conditions.

Hybrid Assembly Solutions

Many modern PCBs require a combination of SMT and THT techniques to accommodate diverse components. MTI offers hybrid assembly solutions that seamlessly integrate both technologies, providing flexibility and ensuring that all components, regardless of their mounting requirements, are assembled to perfection.

Automated Optical Inspection (AOI) and Quality Control

Ensuring Defect-Free Assembly

Quality control is paramount in PCB assembly, and MTI employs Automated Optical Inspection (AOI) to ensure that every board is free from defects. AOI systems use advanced imaging technology to inspect solder joints, component placement, and overall assembly quality. By identifying and addressing potential issues early in the assembly process, MTI guarantees that our customers receive defect-free PCBs that meet their specifications.

In-Circuit and Functional Testing

In addition to AOI, MTI provides comprehensive in-circuit and functional testing services to verify the performance of assembled PCBs. These tests ensure that all electrical connections are correct and that the PCB functions as intended under real-world conditions. Our rigorous testing protocols help reduce the risk of product failures, improving overall reliability and customer satisfaction.

Customization and Flexibility in PCB Assembly

Tailored Solutions for Unique Requirements

Every electronics manufacturing project has its unique requirements, and MTI offers customized PCB assembly solutions to meet these specific needs. Whether it’s a low-volume prototype or a high-volume production run, we work closely with our clients to develop assembly processes that align with their goals. Our flexible approach allows us to accommodate a wide range of design specifications, component types, and assembly techniques.

Rapid Prototyping and Quick Turnaround

In the fast-paced electronics industry, time-to-market is crucial. MTI provides rapid prototyping services that allow manufacturers to quickly test and iterate on their designs. Our quick turnaround times ensure that prototypes are assembled and delivered promptly, enabling our clients to accelerate their product development cycles and bring their innovations to market faster.

The Benefits of Partnering with MTI for PCB Assembly

Expertise and Innovation

MTI brings decades of experience and a commitment to innovation in PCB assembly. Our team of engineers and technicians stays at the forefront of industry advancements, continuously refining our processes and adopting new technologies to enhance our assembly capabilities. This expertise ensures that our clients receive cutting-edge solutions that drive the success of their products.

Cost-Effective Solutions

While maintaining the highest standards of quality, MTI is also dedicated to providing cost-effective PCB assembly solutions. We optimize our manufacturing processes to reduce waste, improve efficiency, and deliver value to our customers. By offering competitive pricing without compromising on quality, we help electronics manufacturers achieve their financial objectives while producing top-tier products.

Comprehensive Support and Collaboration

At MTI, we believe in building strong, collaborative relationships with our clients. From initial design consultation to final delivery, we provide comprehensive support at every stage of the PCB assembly process. Our team is always available to offer technical guidance, address challenges, and ensure that our clients’ projects are completed on time and within budget.

Conclusion

MTI’s innovative PCB assembly solutions are designed to meet the evolving needs of the electronics manufacturing industry. With advanced technologies such as SMT and THT, rigorous quality control measures, and a commitment to customization and flexibility, we provide our clients with the tools they need to succeed. Whether you are developing cutting-edge consumer electronics or industrial equipment, MTI is your trusted partner for reliable, high-quality PCB assembly.