In the rapidly evolving world of electronics, the demand for compact, efficient, and high-functionality devices is ever-growing. MTI, a premier PCB assembly manufacturer, specializes in producing multilayer PCBs that cater to the needs of advanced electronic devices. This article explores the features, benefits, and applications of multilayer PCBs, highlighting how MTI’s expertise and cutting-edge technology ensure the best solutions for high-functionality devices.

Understanding Multilayer PCBs

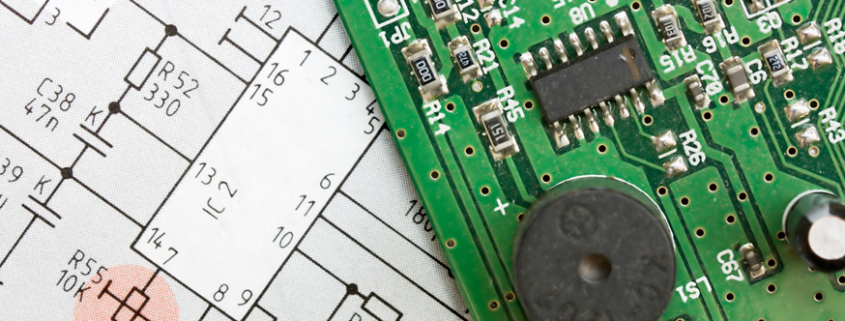

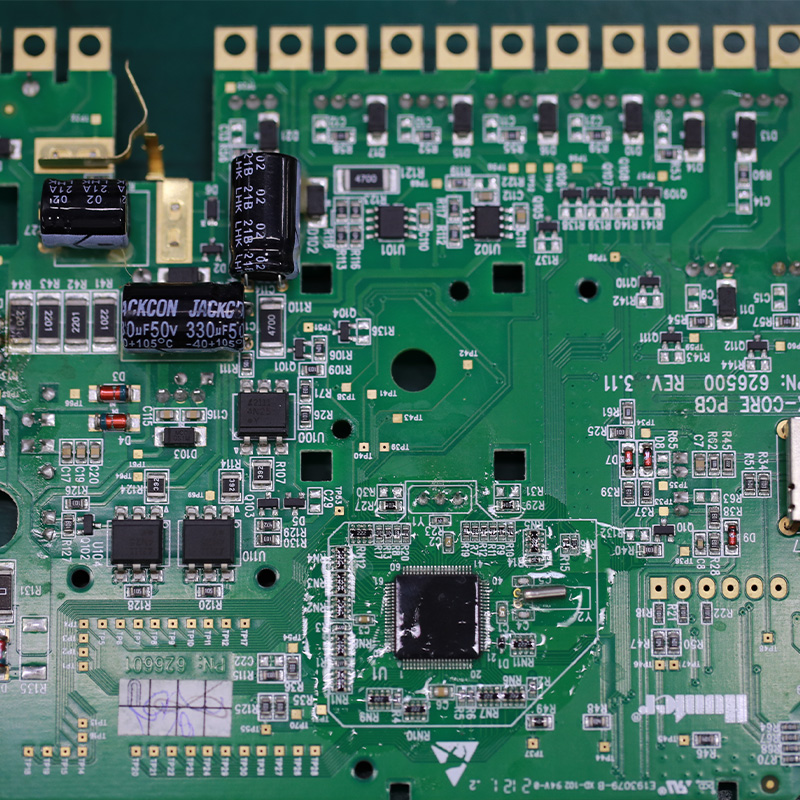

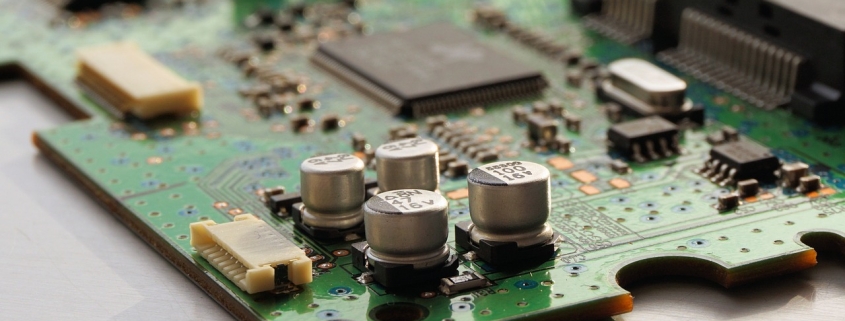

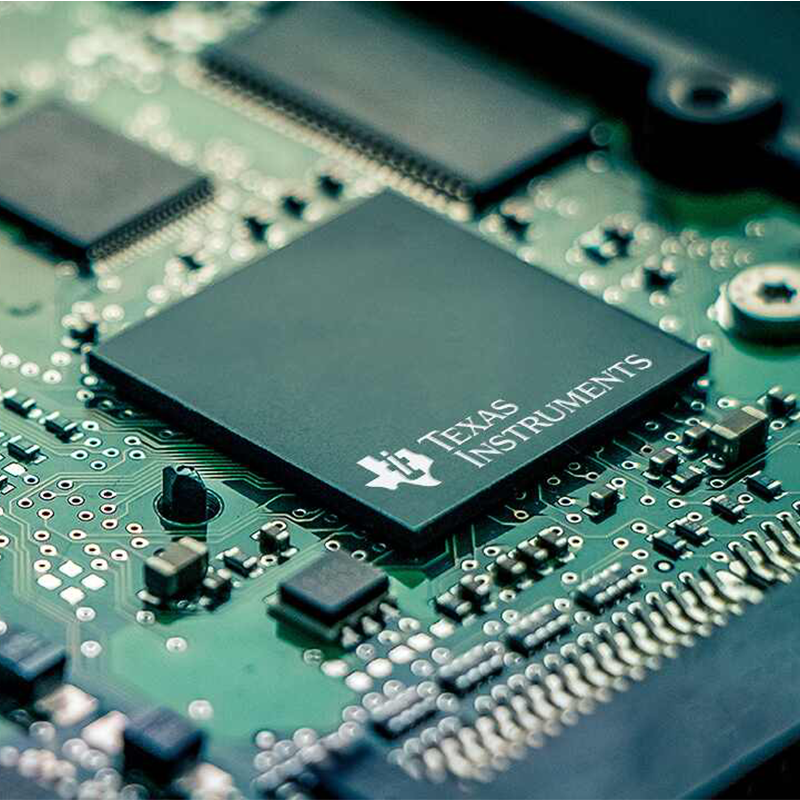

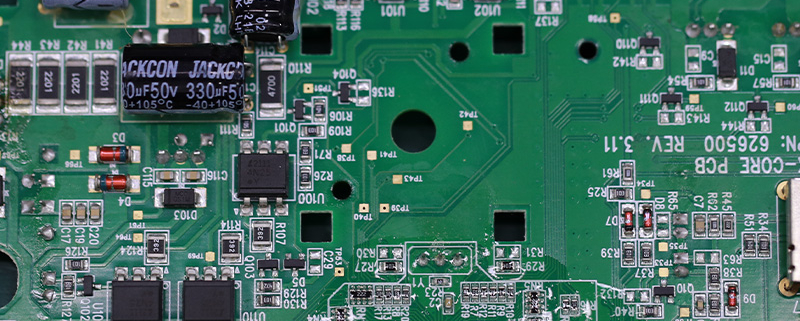

Multilayer PCBs consist of multiple layers of conductive copper and insulating material, stacked together and interconnected by vias. Unlike single or double-layer PCBs, multilayer PCBs can accommodate more complex circuits in a compact form factor, making them ideal for high-functionality devices where space and performance are critical.

Key Features of Multilayer PCBs by MTI

Advanced Layer Configuration

MTI’s multilayer PCBs are designed with advanced configurations to support a wide range of applications:

- Increased Layer Count: We offer PCBs with multiple layers, ranging from 4 to 32 layers, to meet the demands of complex circuitry.

- Signal Integrity: Our designs prioritize signal integrity, ensuring minimal interference and optimal performance, even in high-speed applications.

High-Quality Materials and Construction

Quality materials are essential for the reliability and durability of multilayer PCBs. MTI uses:

- High-Grade Copper Foils: Ensuring excellent electrical conductivity and minimal signal loss.

- Superior Dielectric Materials: Providing reliable insulation and thermal stability, crucial for high-performance applications.

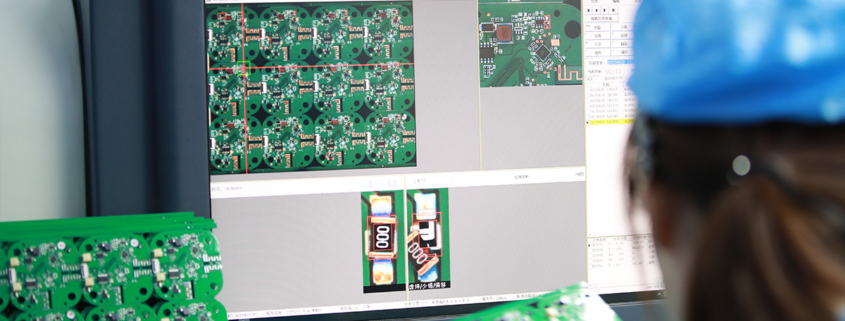

- Precision Drilling and Layer Alignment: Employing state-of-the-art technology for precise drilling and alignment, critical for ensuring connectivity across layers.

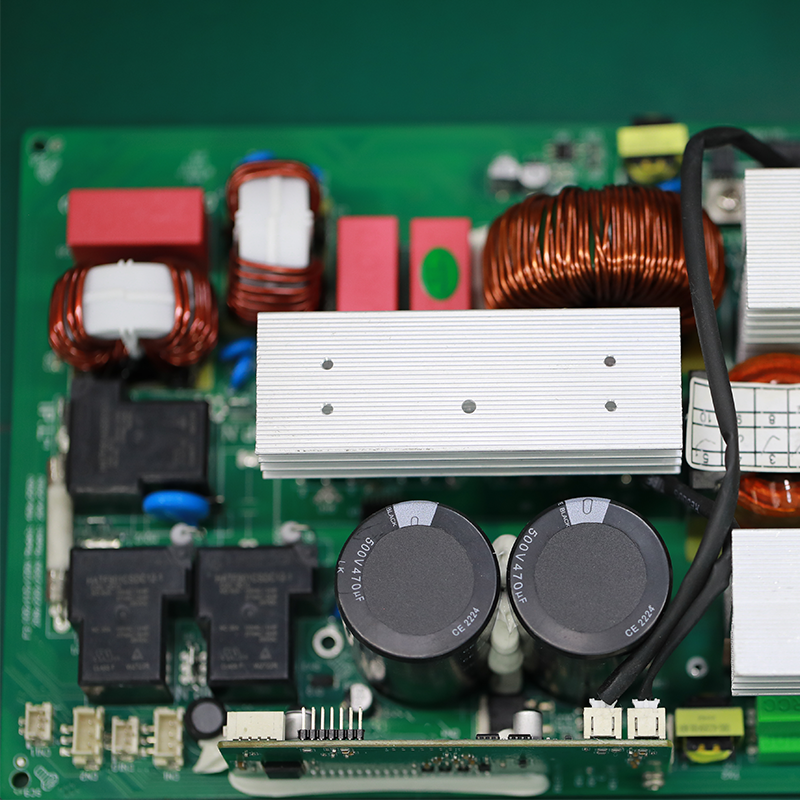

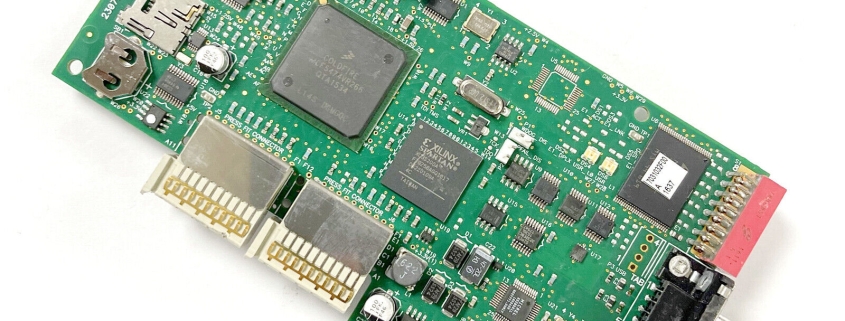

Advanced Manufacturing Processes

MTI employs advanced manufacturing processes to produce multilayer PCBs:

- Lamination Techniques: Using advanced lamination techniques to bond multiple layers securely, ensuring durability and performance.

- Via Technology: Including through-hole, blind, and buried vias to maximize space and connectivity within the PCB.

Benefits of Choosing MTI’s Multilayer PCBs

Compact and Space-Efficient Design

Multilayer PCBs are ideal for high-functionality devices that require compact designs:

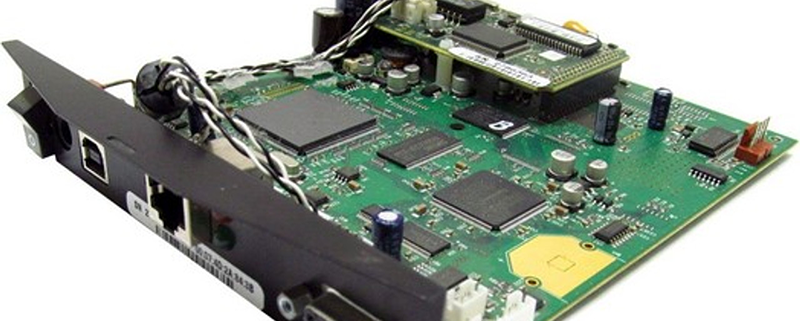

- Reduced Size: By stacking multiple layers, complex circuits can be condensed into a smaller footprint, saving valuable space in device design.

- Higher Component Density: Allows for more components and connections on the PCB, supporting advanced functionalities.

Enhanced Performance and Reliability

MTI’s multilayer PCBs are engineered to deliver superior performance and reliability:

- Improved Electrical Performance: With shorter signal paths and better grounding, multilayer PCBs offer reduced noise and signal interference.

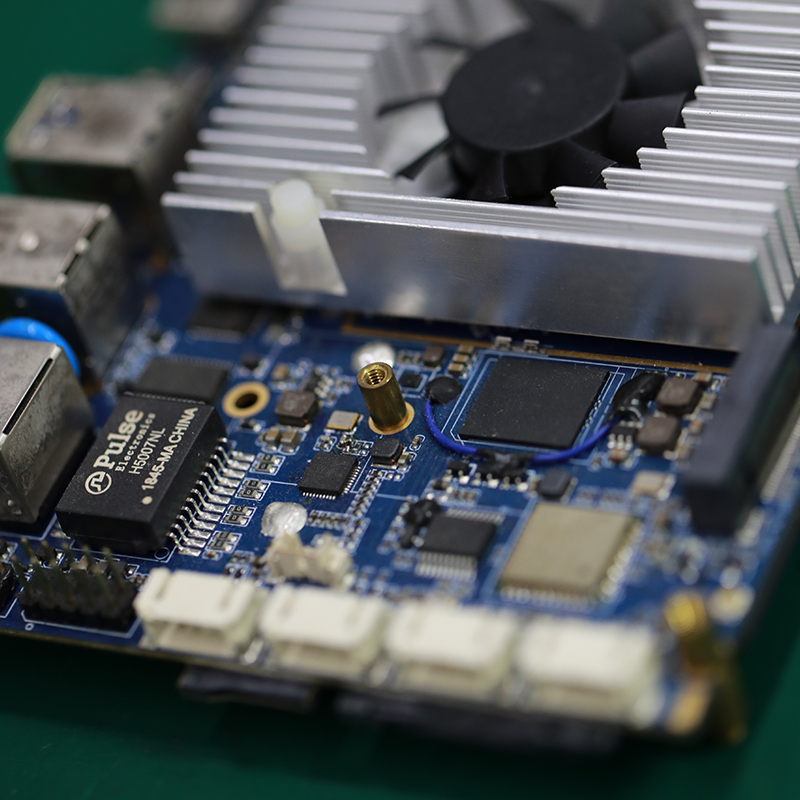

- Thermal Management: Our PCBs are designed to effectively manage heat dissipation, crucial for high-performance and high-power applications.

Customization and Flexibility

MTI provides customization options to meet specific design and functional requirements:

- Custom Layer Stack-Up: Tailored to the unique needs of your device, optimizing for signal integrity, power distribution, and thermal management.

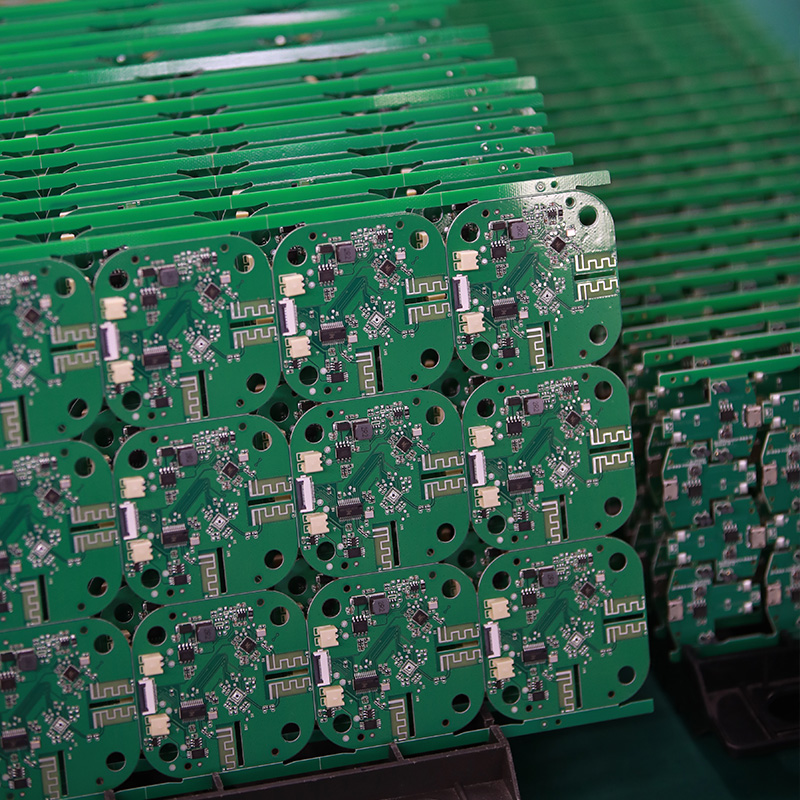

- Flexible Prototyping and Production: We offer both prototype and large-scale production services, adapting to the needs of startups and established companies alike.

Applications of MTI’s Multilayer PCBs

Consumer Electronics

In the consumer electronics industry, MTI’s multilayer PCBs are used in devices such as:

- Smartphones and Tablets: Enabling compact and lightweight designs with advanced features.

- Wearable Devices: Providing the small form factor and high functionality required for smartwatches and fitness trackers.

Automotive and Aerospace

For automotive and aerospace applications, MTI’s multilayer PCBs offer:

- Robust and Reliable Performance: Suitable for infotainment systems, advanced driver-assistance systems (ADAS), and avionics.

- Resistance to Harsh Environments: Designed to withstand temperature extremes, vibration, and other challenging conditions.

Medical Devices

MTI’s multilayer PCBs are also critical in the medical device sector:

- Precision and Reliability: Essential for devices such as diagnostic equipment, medical imaging systems, and patient monitoring devices.

- Compliance with Medical Standards: Manufactured to meet stringent industry regulations and standards, ensuring safety and reliability.

Conclusion

Multilayer PCBs are essential for the development of high-functionality devices, offering compact design, enhanced performance, and reliability. MTI, with its expertise in PCB assembly and advanced manufacturing capabilities, provides top-tier multilayer PCBs tailored to the specific needs of various industries. Whether you are developing consumer electronics, automotive systems, or medical devices, MTI’s multilayer PCBs offer the quality and performance required to bring your innovations to life.

Explore MTI’s range of multilayer PCBs and discover how we can support your projects with cutting-edge technology and exceptional service. Contact us today to learn more about our capabilities and how we can help you achieve your design and production goals.