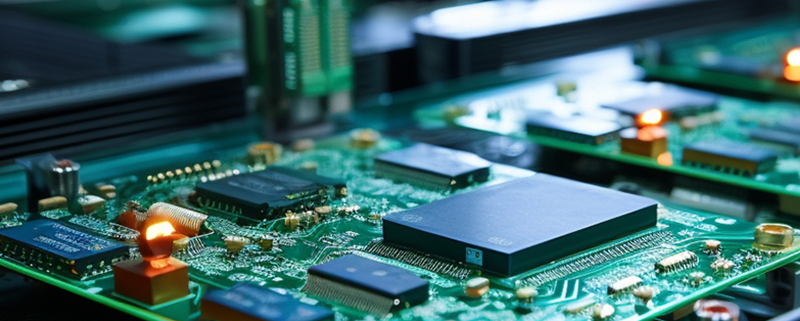

Established in 2004, Mintec Innovation Technology Industry Co., Ltd is a high-tech company specializing in PCB manufacturing, PCB assembly and component procurement services with more than 20 years of experience. We are committed to producing various types of printed circuit boards, mainly including double-sided,single-sided,SMD plug-ins,flexible boards (FPC),metal circuit boards,multi-layer circuit boards,etc.

Our products can be widely used in LED lighting,automotive industries,telecommunication,IOT, etc. And we provide services in after-sales support,logistics,fabrication,inspections,testing, etc. We are proud of our customer-centric approach, providing personalized support and responsive communication at every step of the project.

Flexible Single Layer PCB is one of our PCB products. We will introduce its detailed parameter information and our company advantages to you.

All our products are strictly according to RoHS/REACH regulations, with affordable prices with unparalleled quality.We take care of our product quality, any defect of the goods, we will take responsibility. OEM/ODM service is available.We have full experience in exporting and project management, to secure your order 100%.

| Product name | Flexible Single Layer PCB |

| Keyword | PCBA ,pcb fabrication and assembly,0.8mm pcb,PCB Assembly Company |

| Place of Origin | China |

| Board Thickness | 2~3.2mm |

| Applicable Industries | industrial control, etc. |

| Service | OEM/ODM manufacturing |

| Certificate | ISO-9001:2015, ISO-14001:2015,ISO-13485:2012.UL/CSA |

| Solder Mask Color | Red |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Brunei |

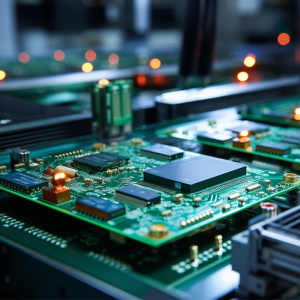

SCHEMATIC DESIGN of Flexible Single Layer PCB

This layout shows the exact appearance and placement of the components on Flexible Single Layer PCB.

MTI ID and MD Design Capabilities