How Does MTI Integrate Noise-Reduction Features in PCB Design?

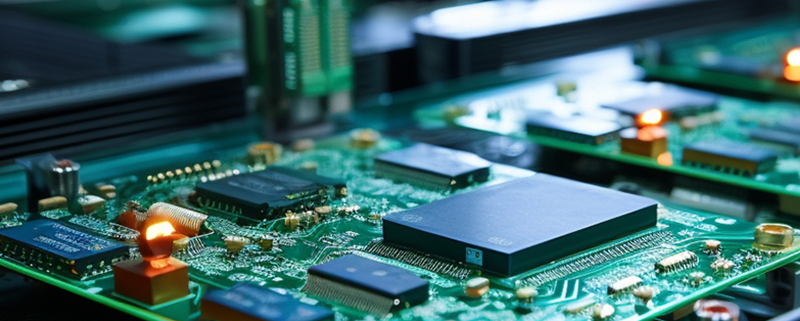

MTI, a leading manufacturer of PCB assemblies, has made significant advancements in reducing noise in modern printed circuit board (PCB) designs. As electronic devices become more complex and compact, managing electromagnetic interference (EMI) and minimizing signal noise has become a critical aspect of PCB design. MTI employs several innovative techniques and strategies to enhance the performance and reliability of their PCBs, especially in environments where low-noise operation is essential, such as medical devices, telecommunications, and automotive electronics.

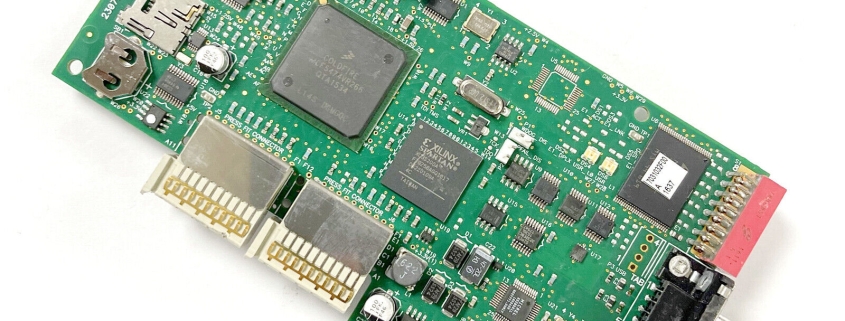

One of the primary methods MTI uses to reduce noise is through optimized component placement and layout design. The company ensures that high-frequency components are placed strategically to minimize interference with low-frequency circuits. This reduces crosstalk between adjacent traces and components, a common source of noise in densely populated PCBs. Additionally, MTI implements multi-layer PCB designs, which allow for effective separation of power, ground, and signal planes. This separation is crucial for isolating noise sources and improving overall signal integrity.

Another noise-reduction feature in MTI’s PCB designs is the use of shielded traces and ground planes. Shielded traces help in blocking external electromagnetic interference, while carefully designed ground planes act as a noise sink, absorbing unwanted signals. These techniques ensure that the PCB performs reliably even in high-EMI environments.

What Materials and Components Contribute to Noise Reduction in MTI PCBs?

MTI also emphasizes the importance of selecting high-quality materials and components to further enhance noise reduction. The use of low-noise components, such as precision capacitors and resistors with minimal tolerances, plays a critical role in maintaining signal integrity. Moreover, MTI employs advanced dielectric materials in their PCB fabrication processes, which help to reduce signal loss and prevent EMI.

The company uses advanced simulation tools during the design phase to analyze and predict noise behavior, allowing them to fine-tune the PCB layout for optimal performance. By doing this, MTI can ensure that their PCBs meet the stringent noise-reduction requirements of industries where noise-free operation is critical, such as aerospace, medical, and consumer electronics.

In addition to the design and materials, MTI incorporates proper decoupling techniques to reduce power supply noise. By placing decoupling capacitors near power pins of integrated circuits, MTI effectively smooths out voltage fluctuations that could lead to noise. These design principles ensure that their PCBs maintain high efficiency and reliability even under demanding operational conditions.

Peer Product Comparison: How Do MTI PCBs Compare with Competitors in Noise-Reduction Performance?

When comparing MTI’s noise-reduction capabilities with other PCB assembly manufacturers such as TTM Technologies, Jabil, and Sanmina, MTI excels in offering a combination of high-performance design at a competitive cost. While all these companies focus on reducing noise, MTI’s attention to layout optimization and component selection often results in superior performance, especially in highly sensitive applications.

Design Efficiency

Compared to competitors like TTM Technologies, MTI’s PCBs are often designed with a more comprehensive approach to noise control. While TTM and Jabil provide high-quality PCBs with good noise-reduction features, MTI’s focus on grounding strategies and multi-layer separation delivers enhanced noise isolation, making them a preferred option for industries that demand precision and low noise.

Cost vs. Performance

MTI’s PCBs tend to be more cost-effective compared to Jabil and Sanmina, especially when noise reduction is a top priority. MTI manages to offer competitive pricing while maintaining excellent noise-reduction features, ensuring that customers do not have to compromise on performance or budget. Their ability to integrate advanced noise-reduction techniques into designs without inflating costs gives them an edge over many industry competitors.

Conclusion

MTI has established itself as a leader in PCB assembly with a strong emphasis on noise reduction in modern PCB design. Their innovative approach, involving optimized component placement, shielding, and high-quality material selection, ensures that their PCBs meet the most stringent noise-reduction requirements. When compared to other industry leaders like TTM Technologies and Jabil, MTI’s products offer an exceptional balance of performance and affordability. These features make MTI an ideal partner for industries where minimizing noise is critical to device performance and reliability.