How PCB Design Impacts Electronic Performance

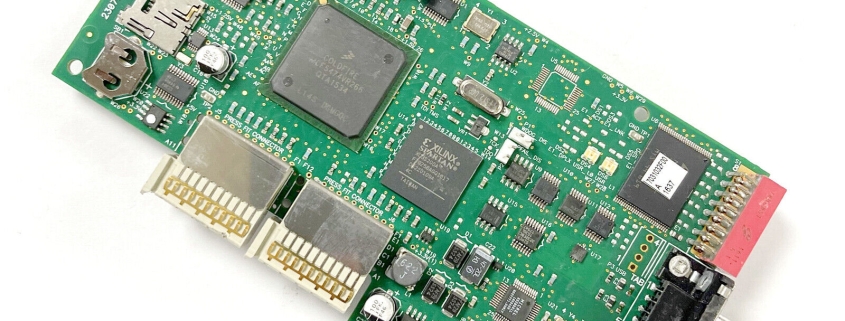

At MTI, a leading PCB assembly manufacturer, we understand that PCB design is a critical factor that directly impacts the performance of electronic devices. A well-designed PCB not only ensures efficient functionality but also enhances the reliability and longevity of the electronic product. In this article, we will explore how PCB design influences electronic performance and why it is essential to get it right from the outset.

The Role of PCB Layout in Signal Integrity

One of the most significant aspects of PCB design that affects electronic performance is the layout. The arrangement of components, traces, and vias on a PCB determines how signals travel through the circuit. Poor layout can lead to signal degradation, crosstalk, and electromagnetic interference (EMI), all of which can impair the performance of the device. MTI employs advanced design techniques to optimize PCB layouts, ensuring that signal integrity is maintained throughout the board. This involves careful placement of components, appropriate routing of high-speed signals, and the use of shielding to minimize interference.

How Does Component Placement Affect Thermal Management?

Thermal management is another critical factor influenced by PCB design. The placement of components on a PCB can significantly impact heat dissipation. If heat-generating components are not adequately spaced or if thermal vias are not used effectively, it can lead to overheating and potential failure of the device. MTI takes thermal considerations seriously by strategically placing components and incorporating thermal management features into the PCB design. This not only prolongs the life of the electronic device but also ensures consistent performance even under demanding conditions.

The Importance of Layer Stack-Up in Multilayer PCBs

Multilayer PCBs are common in complex electronic devices, and the layer stack-up plays a crucial role in their performance. The stack-up refers to the arrangement of the different layers of a PCB, including power, ground, and signal layers. A well-designed stack-up minimizes the potential for interference between layers and improves signal integrity. MTI’s expertise in multilayer PCB design ensures that the layer stack-up is optimized for each specific application, resulting in enhanced electronic performance and reliability.

Material Selection: Choosing the Right Substrate for Optimal Performance

The choice of materials used in PCB manufacturing also significantly impacts electronic performance. The substrate material, in particular, affects factors such as signal speed, thermal conductivity, and overall durability. MTI carefully selects high-quality materials that match the performance requirements of each project. For example, for high-frequency applications, low-loss materials are chosen to reduce signal attenuation, while materials with high thermal conductivity are selected for designs requiring effective heat dissipation.

How Does PCB Design Impact Manufacturing and Assembly?

PCB design not only affects the performance of the final electronic product but also influences the manufacturing and assembly processes. A design that is difficult to manufacture can lead to higher production costs and longer lead times. MTI integrates design for manufacturability (DFM) principles into the PCB design process to ensure that the design is optimized for efficient and cost-effective production. This includes considerations such as component accessibility, ease of assembly, and the minimization of manufacturing defects.

Ensuring Compliance with Industry Standards and Regulations

Compliance with industry standards and regulations is essential for the performance and safety of electronic devices. PCB design plays a pivotal role in meeting these requirements. MTI ensures that all PCB designs adhere to relevant industry standards, such as IPC standards for PCB quality and performance, as well as any specific regulatory requirements for the intended application. This commitment to compliance not only guarantees the safety and reliability of the electronic product but also enhances its marketability.

Conclusion: The Impact of PCB Design on Overall Electronic Performance

In conclusion, PCB design is a fundamental aspect of electronic device performance, influencing everything from signal integrity and thermal management to manufacturing efficiency and regulatory compliance. At MTI, we leverage our extensive expertise in PCB design to ensure that every board we produce meets the highest standards of performance and reliability. By focusing on optimizing layout, component placement, layer stack-up, material selection, and manufacturability, MTI delivers PCB solutions that enhance the overall performance of electronic devices across a wide range of industries.

Box Build

Box Build