Report on the Efficiency of PCBA Processes

MTI is a leading PCB assembly Manufacturer

known for its advanced technology, high-quality products, and exceptional customer service. As a key player in the electronics industry, we understand the nuances of PCB manufacturing and fabrication. This article aims to clarify the difference between these two essential processes, providing insight into how MTI leverages both to deliver superior PCBs to our clients.

Understanding PCB Fabrication

What is PCB Fabrication?

PCB fabrication is the process of creating the physical circuit board that will later be used in electronic devices. This involves several steps, including the design, layout, and etching of the board to form the necessary electrical pathways.

Key Steps in PCB Fabrication

- Design and Layout

: The initial phase involves creating a detailed design and layout of the PCB using specialized CAD software. This design includes all the necessary electrical connections and component placements. - Material Selection

: Choosing the right materials is crucial for the board’s performance. Common materials include FR4 (a type of fiberglass), metal, and high-frequency laminates. - Etching and Layering

: The design is transferred onto the board material, and unwanted copper is etched away to create the electrical pathways. Multi-layer boards involve adding and laminating multiple layers of these etched designs. - Drilling

: Precise holes are drilled for component leads and vias (vertical interconnect accesses) to connect different layers of the board. - Plating and Solder Mask Application

: Copper plating is applied to the drilled holes, and a solder mask is added to protect the board and prevent solder bridges.

Advantages of PCB Fabrication

PCB fabrication is a highly specialized process that ensures the foundational integrity of the circuit board. By focusing on quality materials and precision engineering, MTI guarantees that the fabricated boards meet the highest standards of durability and performance.

Cost Performance

Efficient fabrication processes and high-quality materials contribute to excellent cost performance, making MTI’s PCBs a cost-effective choice for wholesalers, distributors, and OEM/ODM clients.

Understanding PCB Manufacturing

What is PCB Manufacturing?

PCB manufacturing encompasses the entire process of bringing a PCB design to life, including both the fabrication of the board itself and the assembly of electronic components onto the board. This comprehensive process ensures that the final product is ready for integration into electronic devices.

Key Steps in PCB Manufacturing

- Fabrication

: As described above, this is the creation of the physical board. - Component Sourcing

: Sourcing the necessary electronic components from reliable suppliers. This involves procuring items like resistors, capacitors, integrated circuits, and connectors. - Assembly

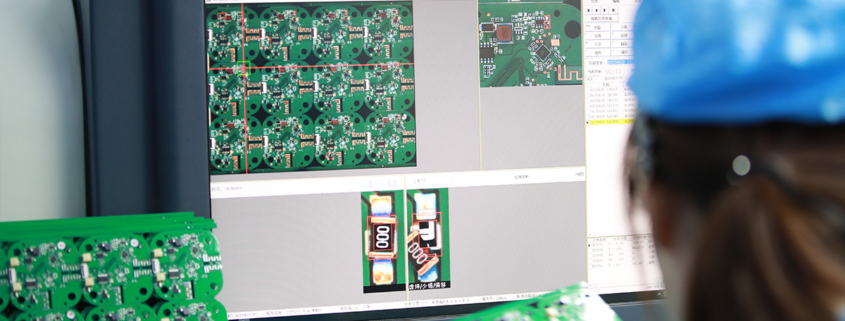

: The components are placed and soldered onto the fabricated board. This can be done using Surface Mount Technology (SMT) or Through-Hole Technology (THT), depending on the design requirements. - Inspection and Testing

: Rigorous testing is conducted to ensure that the assembled PCB functions correctly. This includes electrical tests, functional tests, and visual inspections. - Quality Assurance

: Final quality checks are performed to ensure that the PCBs meet all specifications and standards before shipping to customers.

Advantages of PCB Manufacturing

By handling both fabrication and assembly, MTI ensures seamless integration of all processes, leading to higher quality and reliability in the final product. This comprehensive approach allows us to meet the diverse needs of our clients, from small-scale projects to large OEM/ODM orders.

End-to-End Solutions

Providing end-to-end solutions from design to final assembly enhances our ability to control quality and reduce lead times. This integration is a significant advantage for clients seeking reliable and timely delivery of their PCBs.

Key Differences Between PCB Manufacturing and PCB Fabrication

Scope of Work

- PCB Fabrication

: Focuses solely on creating the physical board. - PCB Manufacturing

: Encompasses fabrication plus the assembly of electronic components onto the board.

Processes Involved

- PCB Fabrication

: Involves design, material selection, etching, drilling, plating, and solder mask application. - PCB Manufacturing

: Includes all fabrication processes plus component sourcing, assembly, inspection, and quality assurance.

End Product

- PCB Fabrication

: Results in a bare board with no components. - PCB Manufacturing

: Delivers a fully assembled and tested PCB ready for use in electronic devices.

Conclusion

Understanding the difference between PCB fabrication and PCB manufacturing is crucial for selecting the right services for your project. At MTI, we offer comprehensive PCB manufacturing solutions that ensure high-quality, reliable, and cost-effective products. Our advanced R&D capabilities, efficient manufacturing processes, and commitment to customer satisfaction make us the ideal partner for all your PCB needs. Whether you are a supplier, agent, or OEM/ODM client, MTI has the expertise and resources to meet your requirements and exceed your expectations.