The Role of PCBA in Modern Electronics

Printed Circuit Board Assembly (PCBA) is at the heart of virtually all modern electronic devices, playing a critical role in the functionality, performance, and reliability of electronic products. As a leading PCB assembly manufacturer, MTI is deeply involved in the production of high-quality PCBAs that drive innovation across various industries. This article explores the essential role of PCBA in modern electronics and how MTI contributes to advancing this technology.

What Is PCBA and Why Is It Important in Electronics?

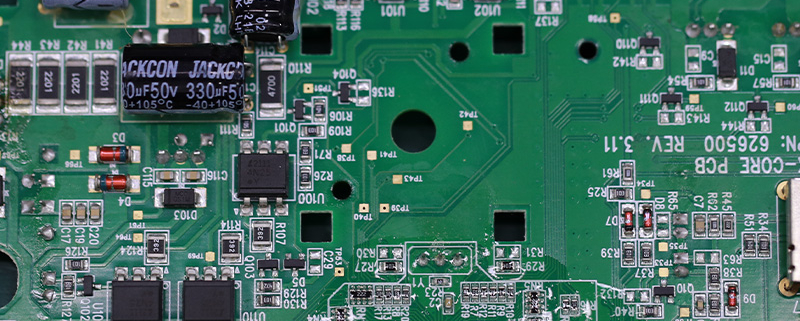

PCBA refers to the process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic circuit. Here’s why PCBA is crucial:

- Core Functionality: The PCBA is responsible for the core functionality of electronic devices, facilitating the connection and interaction of various electronic components, such as resistors, capacitors, transistors, and microcontrollers.

- Compact and Efficient Design: Modern electronics demand compact and efficient designs. PCBA allows for the integration of complex circuits within a small footprint, enabling the development of sleek, lightweight, and portable devices.

- Reliability and Durability: The quality of the PCBA directly impacts the reliability and durability of electronic products. A well-manufactured PCBA ensures that devices perform consistently over time, reducing the likelihood of malfunctions and extending product life.

How Does PCBA Support Technological Advancements in Various Industries?

PCBA is a driving force behind technological advancements across multiple industries:

- Consumer Electronics: From smartphones and laptops to smart home devices, PCBA enables the sophisticated functionalities that consumers expect. MTI’s expertise in high-density interconnect (HDI) PCBAs allows for the creation of smaller, faster, and more powerful consumer electronics.

- Automotive Industry: Modern vehicles rely on advanced electronic systems for safety, navigation, entertainment, and efficiency. MTI produces robust PCBAs that meet the stringent requirements of the automotive industry, ensuring reliable performance in harsh environments.

- Healthcare and Medical Devices: In the healthcare sector, PCBA is integral to the operation of critical medical devices such as diagnostic equipment, monitoring systems, and wearable health trackers. MTI provides precision PCBAs that meet the high standards of medical applications, supporting accurate and reliable healthcare solutions.

- Industrial Automation: The industrial sector benefits from PCBA in the development of automated machinery, robotics, and control systems. MTI’s durable and high-performance PCBAs contribute to the efficiency and reliability of industrial automation technologies.

What Are the Key Components and Processes Involved in PCBA?

The PCBA process involves several key components and steps that are essential for creating functional electronics:

What Are the Main Components Used in PCBA?

Key components in PCBA include:

- PCBs (Printed Circuit Boards): The PCB serves as the foundation, providing the necessary pathways for electrical signals. MTI specializes in manufacturing high-quality PCBs that support complex circuit designs.

- Electronic Components: These include active components like microcontrollers and semiconductors, as well as passive components such as resistors and capacitors. The selection and integration of these components are critical for achieving the desired functionality.

- Soldering Materials: Solder paste and flux are used to securely attach components to the PCB. MTI uses advanced soldering techniques, including surface-mount technology (SMT) and through-hole technology, to ensure reliable connections.

What Are the Key Steps in the PCBA Process?

The PCBA process typically involves the following steps:

- Component Placement: Automated machines place components onto the PCB with high precision. MTI’s state-of-the-art equipment ensures accurate placement, even for the smallest components.

- Soldering: Components are soldered to the PCB using techniques such as reflow soldering or wave soldering. MTI’s advanced soldering processes guarantee strong, reliable connections that withstand environmental stresses.

- Inspection and Testing: The assembled PCBA undergoes rigorous inspection and testing to verify its functionality and quality. MTI employs automated optical inspection (AOI), X-ray inspection, and functional testing to identify and correct any defects before final delivery.

How Does MTI Ensure Quality and Innovation in PCBA Manufacturing?

Quality and innovation are at the core of MTI’s approach to PCBA manufacturing:

What Quality Assurance Practices Does MTI Implement?

MTI maintains strict quality control throughout the PCBA process:

- Standard Compliance: MTI adheres to industry standards such as IPC, ISO, and RoHS to ensure that all PCBAs meet the highest quality and safety requirements.

- Continuous Monitoring: Real-time monitoring and data analysis are used to continuously improve processes and address potential issues before they impact product quality.

- Advanced Testing: MTI’s comprehensive testing protocols, including environmental stress testing and reliability testing, ensure that every PCBA is built to perform reliably under real-world conditions.

How Does MTI Drive Innovation in PCBA?

MTI is committed to staying at the forefront of PCBA technology:

- R&D Investments: MTI invests in research and development to explore new materials, manufacturing techniques, and design methodologies. This commitment to innovation enables MTI to offer cutting-edge PCBAs that meet the evolving demands of modern electronics.

- Customized Solutions: MTI provides tailored PCBA solutions that meet the specific needs of each client, whether it’s a unique design requirement, a challenging environment, or a need for rapid prototyping and production.

- Sustainability Initiatives: MTI is also focused on sustainable manufacturing practices, incorporating eco-friendly materials and processes to reduce environmental impact while maintaining high performance and reliability.

Conclusion: The Role of PCBA in Modern Electronics

PCBA is an essential component of modern electronics, enabling the functionality, efficiency, and reliability that consumers and industries demand. As a leading PCB assembly manufacturer, MTI plays a vital role in advancing PCBA technology through quality manufacturing, innovative solutions, and a commitment to customer satisfaction. By understanding the importance of PCBA and selecting a trusted partner like MTI, businesses can ensure the success of their electronic products in today’s competitive market. Whether for consumer electronics, automotive applications, healthcare devices, or industrial systems, MTI provides the expertise and technology needed to bring cutting-edge electronic products to life.

Tags: PCB Manufacturer,PCB service,PCB Design & engineering,PCB Manufacturing,PCB Assemblies,FIRMWARE DEVELOPMENT,SMT,PCB TPH Assembly,Box Build Assembly,NPI PCBA PROTOTYPE