How PCBA Manufacturing Improves Electronics Production by MTI

At MTI, a leading PCB assembly (PCBA) manufacturer, we understand the pivotal role that PCBA manufacturing plays in enhancing the efficiency, quality, and innovation in electronics production. As electronics continue to evolve and become more complex, the need for high-quality, reliable, and cost-effective PCBA solutions is greater than ever. In this article, we explore how PCBA manufacturing at MTI improves electronics production, driving advancements across various industries.

Understanding PCBA Manufacturing

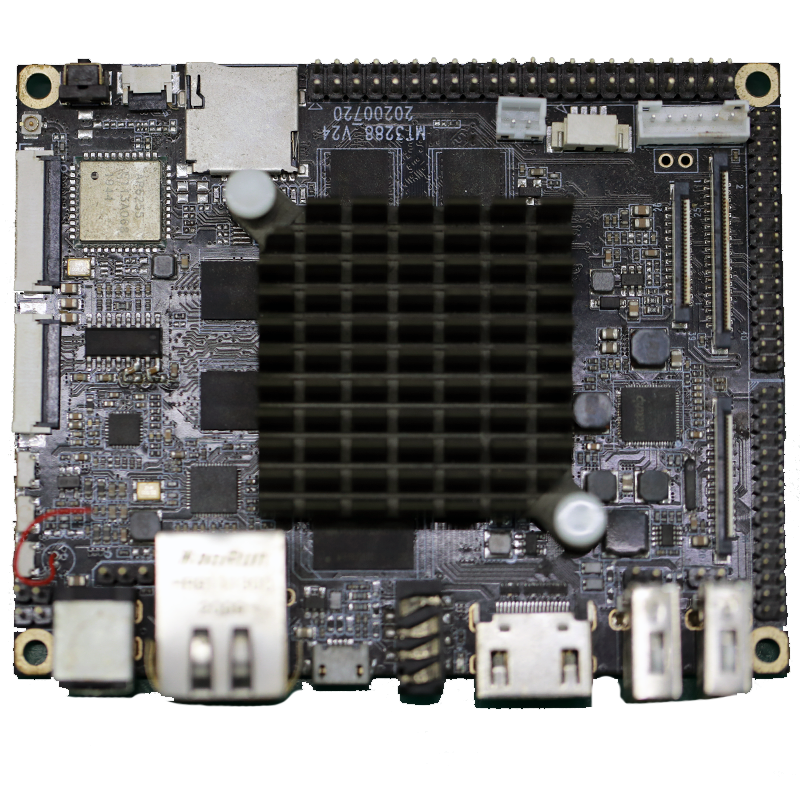

What is PCBA Manufacturing?

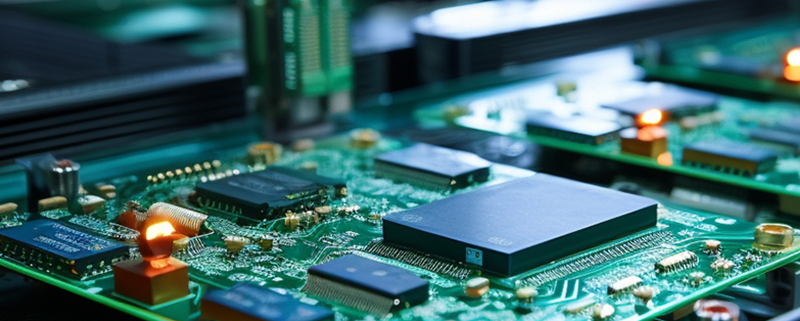

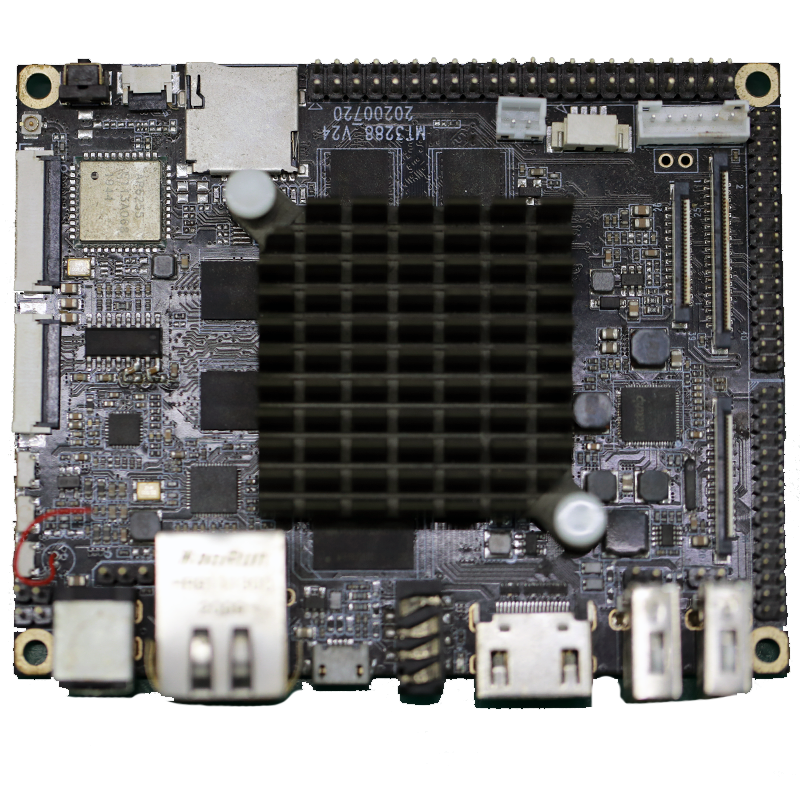

PCBA manufacturing involves the process of assembling electronic components onto a printed circuit board (PCB) to create a fully functional circuit. This process includes several key steps such as soldering components, testing for functionality, and ensuring the integrity of electrical connections. At MTI, we specialize in providing comprehensive PCBA services, from design and prototyping to full-scale production, ensuring that our clients receive high-performance electronics.

The Importance of PCBA in Electronics

PCBA is the foundation of modern electronic devices, serving as the core that powers everything from consumer gadgets to industrial machinery. The quality and reliability of a PCBA directly impact the performance, durability, and user experience of the final product. MTI’s advanced PCBA manufacturing capabilities ensure that our customers’ products meet the highest standards of excellence, enabling them to compete effectively in the market.

Enhancing Efficiency in Electronics Production

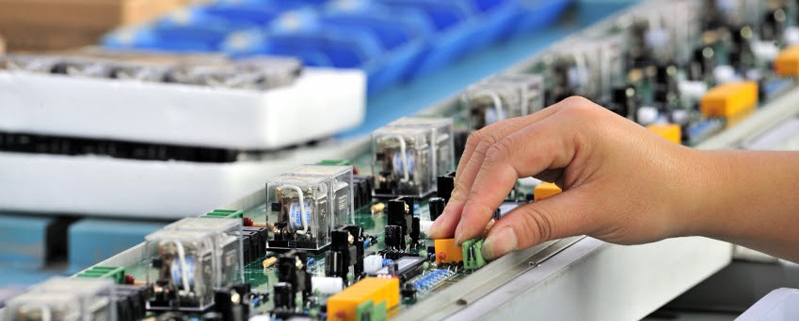

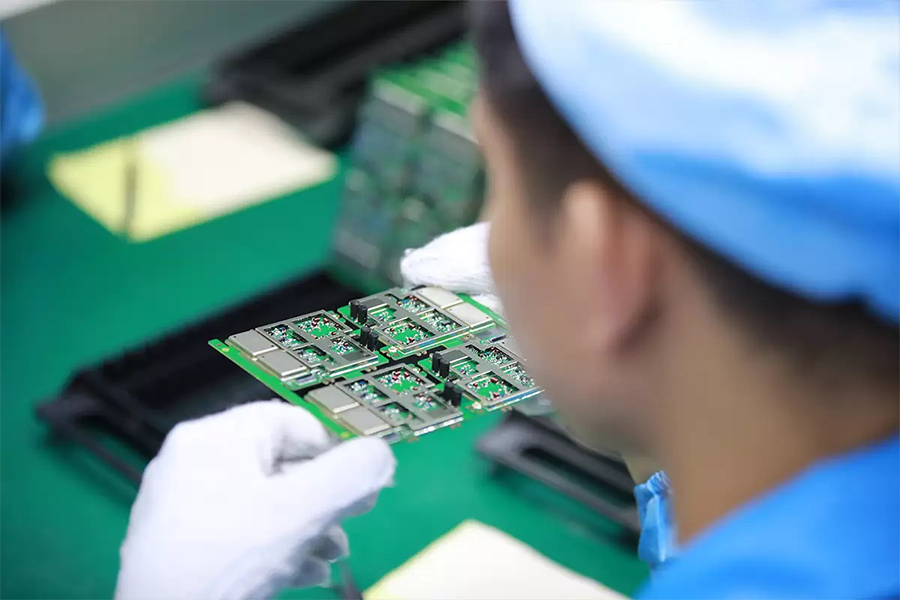

Streamlined Manufacturing Processes

MTI employs streamlined manufacturing processes that reduce production time and minimize waste. By integrating advanced automation and precision engineering, we enhance the efficiency of PCBA production, allowing for faster turnaround times without sacrificing quality. This efficiency is critical in today’s fast-paced electronics industry, where time-to-market can make a significant difference in a product’s success.

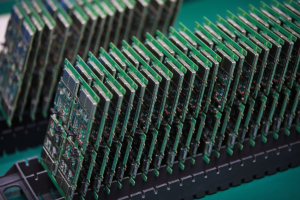

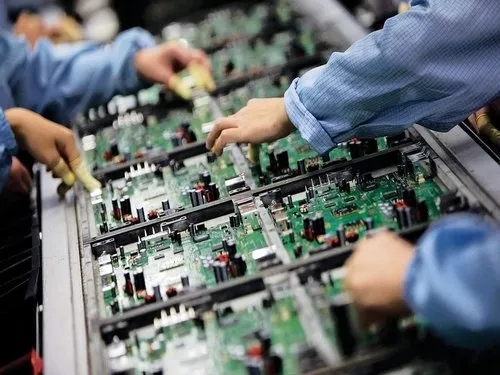

High-Volume Production Capabilities

For electronics manufacturers, the ability to scale production quickly and efficiently is essential. MTI offers high-volume production capabilities that meet the demands of large-scale projects while maintaining consistent quality. Our facilities are equipped to handle extensive production runs, ensuring that our clients can meet their market demands on time and within budget.

Cost-Effective Manufacturing Solutions

Reducing production costs while maintaining high quality is a key challenge in electronics manufacturing. MTI addresses this challenge by optimizing our PCBA manufacturing processes to reduce overhead, material waste, and labor costs. Our cost-effective solutions help our clients achieve competitive pricing in the market, making their products more accessible to consumers without compromising on performance.

Improving Quality and Reliability

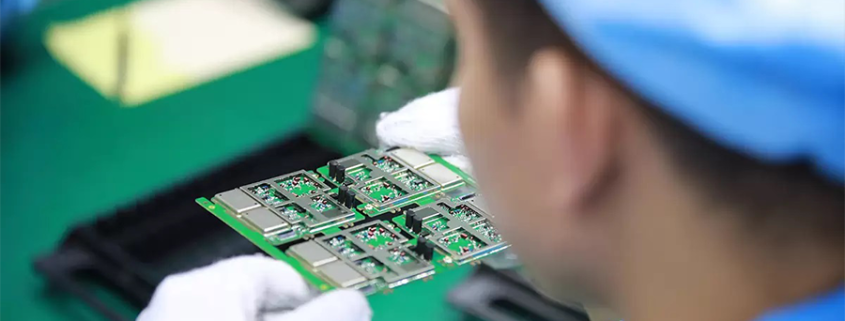

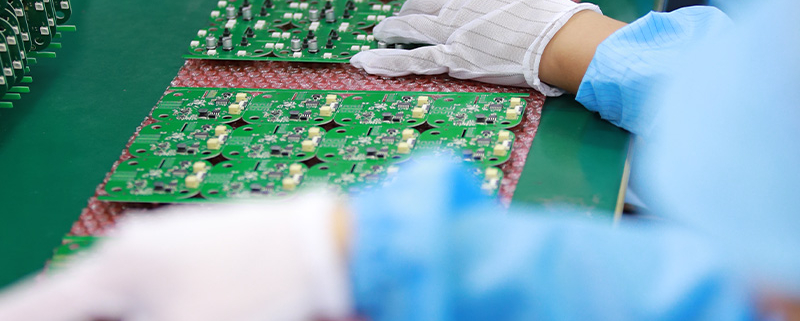

Rigorous Quality Control Measures

Quality control is at the heart of MTI’s PCBA manufacturing process. We implement rigorous testing and inspection procedures at every stage of production, from component selection to final assembly. Our quality control measures include automated optical inspection (AOI), in-circuit testing (ICT), and functional testing, ensuring that each PCBA meets the highest standards of reliability and performance.

Advanced Testing and Validation

MTI’s commitment to quality extends to our advanced testing and validation services. We utilize cutting-edge testing technologies to simulate real-world operating conditions, identifying potential issues before they reach the market. This proactive approach to quality assurance helps reduce the risk of product failures and enhances the long-term reliability of our customers’ electronics.

Robust Design and Engineering Support

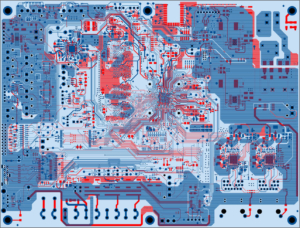

At MTI, we provide comprehensive design and engineering support to optimize the performance and reliability of each PCBA. Our team of experienced engineers works closely with clients to refine PCB designs, select appropriate components, and ensure that every aspect of the assembly process is aligned with the desired specifications. This collaboration results in more robust and reliable electronic products that meet or exceed customer expectations.

Driving Innovation in Electronics

Rapid Prototyping and Iteration

Innovation in electronics often requires rapid prototyping and iteration to bring new ideas to life. MTI offers rapid prototyping services that allow our clients to quickly test and refine their designs. Our fast and flexible prototyping capabilities enable manufacturers to experiment with new technologies, materials, and designs, accelerating the development process and reducing time-to-market for innovative products.

Customization and Flexibility

MTI understands that every electronics project has unique requirements, and we offer a high degree of customization and flexibility in our PCBA manufacturing services. Whether it’s a custom PCB layout, specific component selection, or unique assembly techniques, we work with our clients to tailor our solutions to their exact needs. This flexibility allows for greater creativity and innovation in product development, enabling manufacturers to stand out in a competitive market.

Supporting Emerging Technologies

As new technologies emerge, the demand for specialized PCBA solutions grows. MTI is at the forefront of supporting emerging technologies such as IoT, wearable devices, and advanced sensors. Our expertise in handling complex PCBA requirements positions us as a trusted partner for companies looking to push the boundaries of what’s possible in electronics.

Enhancing Supply Chain Management

Integrated Supply Chain Solutions

MTI’s PCBA manufacturing services include integrated supply chain management, ensuring that all components and materials are sourced, managed, and delivered efficiently. By managing the entire supply chain, we help our clients reduce lead times, lower costs, and maintain consistent quality throughout the production process.

Global Sourcing and Logistics

In today’s globalized market, access to high-quality components at competitive prices is essential. MTI leverages its global network of suppliers to source the best materials and components, ensuring that our clients receive the highest quality at the best value. Our logistics expertise ensures timely delivery, even for large-scale production runs, enabling manufacturers to maintain their production schedules and meet market demands.

Conclusion

PCBA manufacturing is a critical component of modern electronics production, driving efficiency, quality, innovation, and supply chain management. At MTI, we are dedicated to providing advanced PCBA solutions that enhance every aspect of electronics manufacturing. From streamlined production processes and rigorous quality control to supporting innovation and optimizing supply chains, MTI is your trusted partner for improving the performance and success of your electronic products.