Comparing PCBA and Traditional Assembly Methods

What is PCBA?

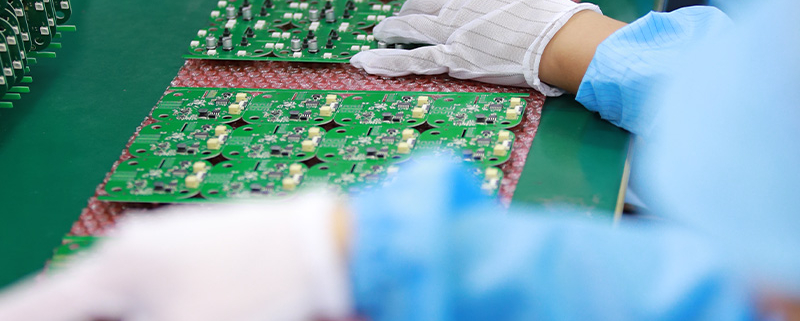

Printed Circuit Board Assembly (PCBA) is the process of attaching electronic components onto a printed circuit board (PCB). This assembly can involve both surface mount technology (SMT) and through-hole technology (THT) methods. PCBA has become the backbone of modern electronics manufacturing, enabling the production of highly complex electronic devices with high precision and efficiency.

How Does Traditional Assembly Differ from PCBA?

Traditional assembly methods often involve manual or semi-automated processes, where components are hand-soldered or attached to a PCB. While these methods have been reliable in the past, they are increasingly becoming outdated due to their time-consuming nature, lower precision, and higher risk of human error. PCBA, on the other hand, utilizes automated processes that significantly enhance production speed, accuracy, and reliability.

Why is Automation in PCBA Beneficial?

Automation in PCBA brings numerous benefits to manufacturers like MTI. Firstly, it allows for higher production volumes while maintaining consistent quality. Automated processes are less prone to errors, reducing the need for rework and leading to cost savings. Additionally, automation enables the handling of smaller and more intricate components that are challenging to assemble manually.

What Role Does Surface Mount Technology Play in PCBA?

Surface Mount Technology (SMT) is a key component of PCBA. It involves mounting components directly onto the surface of the PCB, eliminating the need for drilling holes as required in through-hole technology. SMT is preferred for its ability to accommodate smaller components and create more compact designs, which is essential in modern electronics.

How Does Through-Hole Technology Complement SMT?

While SMT is ideal for smaller, more delicate components, through-hole technology is still used for components that require stronger mechanical bonds. This combination of SMT and THT in PCBA allows manufacturers like MTI to offer versatile solutions that cater to different product requirements, ensuring durability and reliability.

What Are the Quality Control Measures in PCBA?

Quality control is a critical aspect of PCBA, especially for a reputable PCB assembly manufacturer like MTI. The process involves rigorous testing at various stages, including automated optical inspection (AOI), X-ray inspection, and functional testing. These measures ensure that the assembled PCBs meet the required standards and function as intended in the final product.

How Does PCBA Improve Efficiency and Cost-Effectiveness?

PCBA improves efficiency through its automated processes, reducing production time and labor costs. The precision of automated assembly also minimizes material wastage, leading to more cost-effective production. For companies like MTI, this means the ability to offer competitive pricing without compromising on quality.

What Are the Environmental Benefits of PCBA?

PCBA contributes to more sustainable manufacturing practices. The precision of automated processes reduces the amount of material waste and energy consumption. Furthermore, the use of lead-free solder and other environmentally friendly materials in PCBA helps in reducing the environmental impact of electronic manufacturing.

How is MTI Advancing PCBA Technology?

MTI, as a leading PCB assembly manufacturer, is at the forefront of advancing PCBA technology. By investing in state-of-the-art equipment and continually updating their processes, MTI ensures that they meet the evolving demands of the electronics industry. Their commitment to innovation and quality makes them a trusted partner for businesses looking to produce reliable and cutting-edge electronic devices.

What Are the Future Trends in PCBA?

The future of PCBA is likely to see even greater levels of automation, with the integration of artificial intelligence and machine learning to further enhance precision and efficiency. Additionally, the ongoing miniaturization of electronic components will drive advancements in SMT and other assembly technologies. Companies like MTI will continue to lead the charge in adopting these innovations, ensuring they remain competitive in the rapidly evolving electronics market.