Achieving Economies of Scale in PCB Production

In the competitive electronics industry, achieving economies of scale in PCB production is crucial for reducing costs and increasing efficiency. MTI, a leading PCB assembly manufacturer, leverages advanced manufacturing techniques and strategic planning to deliver cost-effective solutions without compromising on quality. This article explores the methods and benefits of achieving economies of scale in PCB production, highlighting MTI’s capabilities and advantages.

Advanced Manufacturing Techniques

MTI employs cutting-edge manufacturing techniques to maximize efficiency and achieve economies of scale.

High-Volume Production

MTI’s factory is equipped with state-of-the-art machinery capable of high-volume production. This capacity allows for the efficient manufacturing of large quantities of PCBs, reducing per-unit costs and optimizing resource utilization.

Automation and Robotics

The integration of automation and robotics in MTI’s manufacturing process enhances precision and speed. Automated systems streamline production workflows, minimize human error, and increase output, contributing significantly to economies of scale.

Strategic Sourcing and Supply Chain Management

Effective sourcing and supply chain management are essential components of achieving economies of scale.

Bulk Material Sourcing

MTI sources materials in bulk from reliable suppliers, ensuring consistent quality while benefiting from volume discounts. This strategic approach reduces material costs and enhances cost performance, providing a competitive advantage.

Efficient Logistics and Distribution

MTI maintains an efficient logistics network that ensures timely delivery of materials and finished products. By optimizing transportation and inventory management, the company minimizes delays and reduces overhead costs.

Customization and Flexibility

MTI offers extensive customization options through its OEM/ODM services, catering to diverse client needs while maintaining cost efficiency.

Tailored PCB Designs

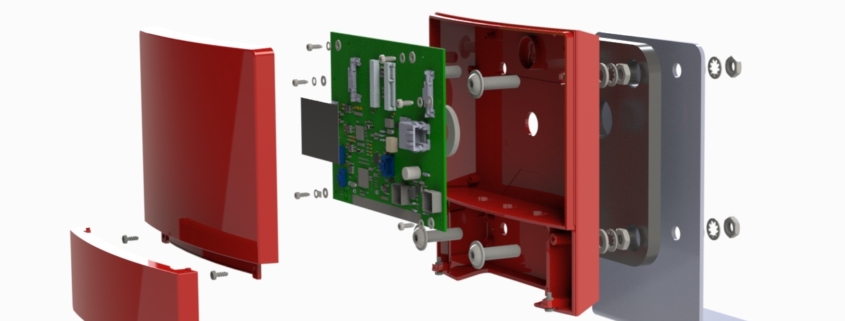

Clients can request tailored PCB designs to meet their specific requirements. MTI’s R&D team collaborates closely with clients to develop custom solutions that align with their project goals, ensuring optimal performance and cost efficiency.

Scalable Production Solutions

MTI’s scalable production solutions accommodate both small and large orders, providing flexibility without sacrificing economies of scale. This adaptability ensures that clients receive high-quality PCBs regardless of order size.

Quality Control and Assurance

Maintaining high-quality standards is crucial for achieving economies of scale without compromising product integrity.

Rigorous Testing Procedures

Every PCB undergoes rigorous testing procedures to ensure it meets stringent quality standards. This comprehensive quality control process minimizes defects and reduces the need for costly rework, enhancing overall cost performance.

Consistent Quality Standards

MTI adheres to consistent quality standards across all production stages. From material selection to final assembly, each step is meticulously monitored to ensure the highest level of quality and reliability.

Cost Performance Benefits

Achieving economies of scale in PCB production provides significant cost performance benefits, making MTI a preferred choice for clients worldwide.

Reduced Production Costs

High-volume production and strategic sourcing reduce overall production costs, enabling MTI to offer competitive pricing. This cost advantage allows clients to maximize their investment and achieve better profitability.

Enhanced Efficiency

Automation, bulk sourcing, and efficient logistics contribute to enhanced production efficiency. This efficiency translates to faster turnaround times, lower operational costs, and improved client satisfaction.

Supply Chain Efficiency

MTI’s well-established supply chain ensures the seamless delivery of products, enhancing their competitive edge in the market.

Reliable Supplier Network

MTI has built a reliable supplier network that ensures the consistent availability of high-quality materials. This network supports uninterrupted production and timely order fulfillment, reinforcing MTI’s reputation as a dependable manufacturer.

Global Distribution Capabilities

MTI’s global distribution capabilities ensure that clients receive their PCBs promptly, regardless of their location. This global reach enhances client satisfaction and supports the company’s growth in international markets.

Conclusion

MTI’s approach to achieving economies of scale in PCB production combines advanced manufacturing techniques, strategic sourcing, and rigorous quality control to deliver cost-effective and high-quality solutions. As a leading PCB assembly manufacturer in China, MTI offers extensive customization options, competitive pricing, and efficient supply chain management.

Tags: PCB Bog,SCHEMATIC DESIGN,PCB LAYOUT,FIRMWARE DEVELOPMENT,SMT,PCB TPH Assembly,Box Build Assembly,NPI PCBA PROTOTYPE