Introduction to MTI

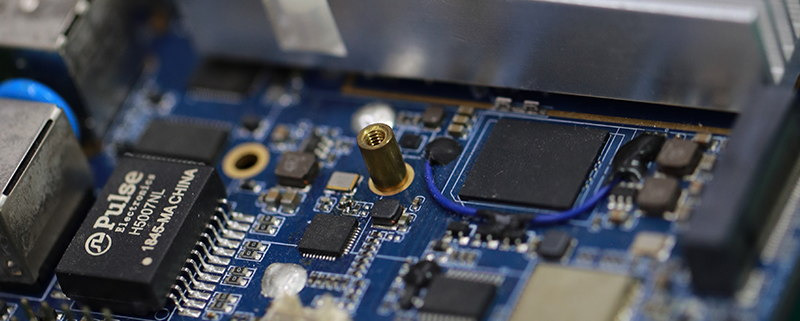

MTI is a premier PCB manufacturing Manufacturer

specializing in the integration of WiFi wireless modules into high-quality PCBs. Our advanced technology and expertise ensure that our products meet the highest standards of performance and reliability. Whether you are an OEM/ODM client, a wholesaler, or a distributor, MTI provides the solutions you need to enhance connectivity and optimize your electronic designs.

Advantages of WiFi Wireless Modules

Superior Connectivity and Performance

WiFi wireless modules are essential for modern electronic devices, offering robust connectivity and high-speed data transfer. These modules are designed to support a wide range of applications, from consumer electronics to industrial systems.

Key Features of WiFi Wireless Modules

- High-Speed Data Transfer

: WiFi modules enable fast and reliable data communication, essential for real-time applications. - Versatile Connectivity

: These modules support various protocols and standards, ensuring compatibility with different devices and networks. - Low Power Consumption

: Designed for efficiency, WiFi modules minimize power usage, making them ideal for battery-operated devices.

Cost Performance

WiFi wireless modules offer excellent cost performance, providing advanced connectivity features at a competitive price. This makes them an attractive option for projects that require reliable wireless communication without compromising on budget.

MTI’s Expertise in PCB Manufacturing

Advanced Design and Engineering

At MTI, our R&D team excels in designing PCBs that integrate WiFi wireless modules seamlessly. Our focus on innovation and precision ensures that our PCBs deliver superior performance and durability.

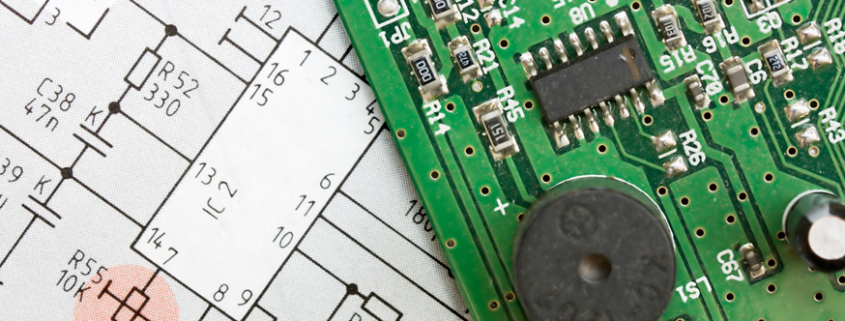

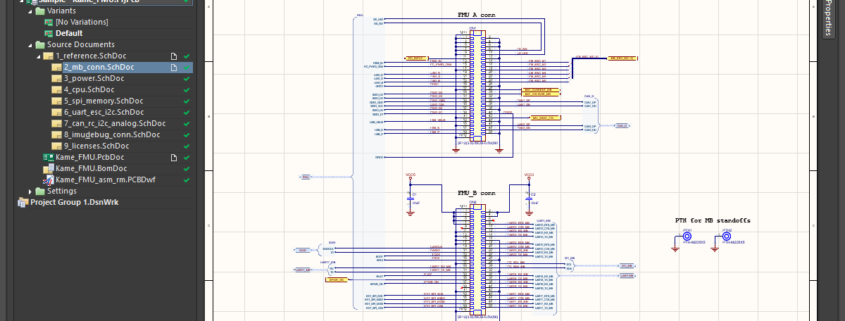

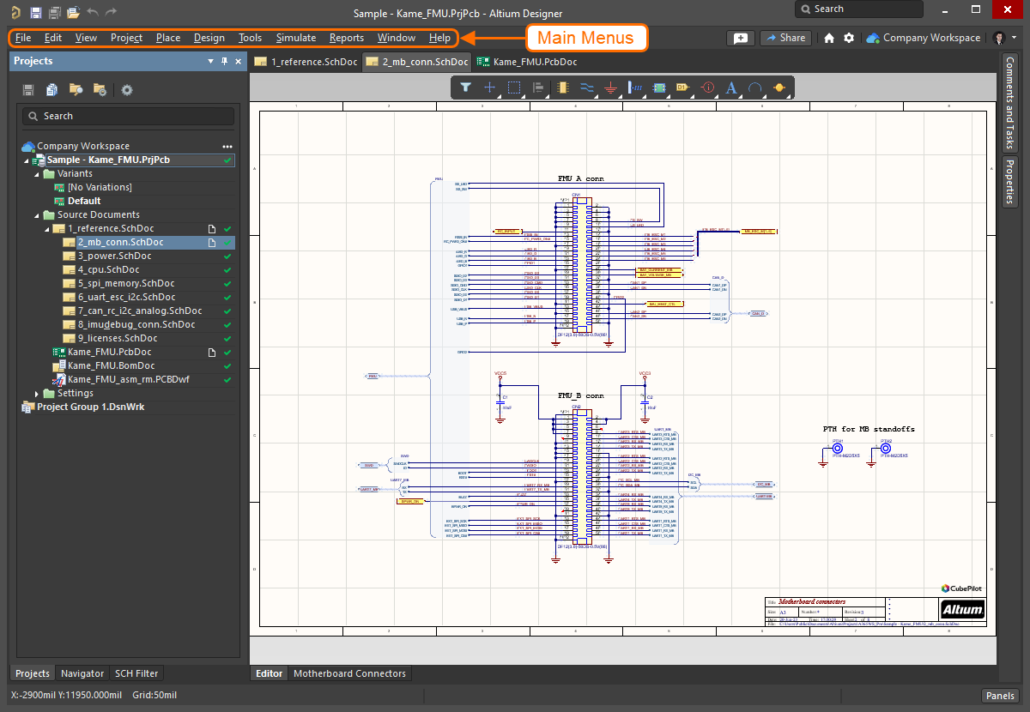

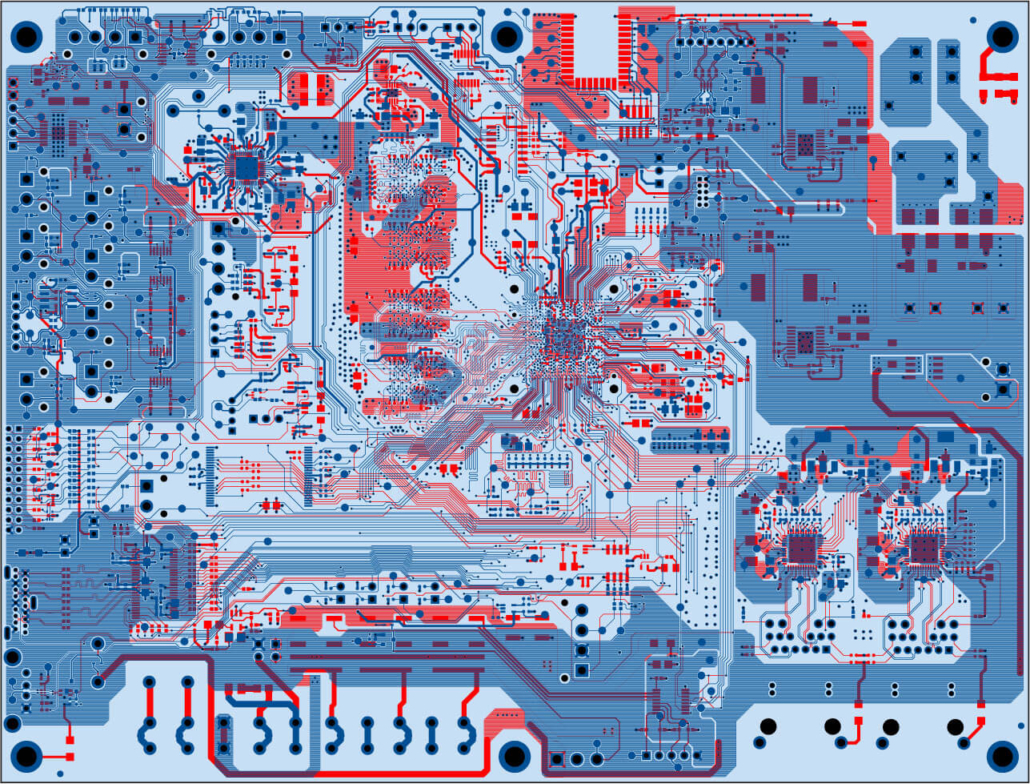

Custom PCB Design

We offer custom PCB design services to meet the specific needs of our clients. Our experienced designers use the latest software to create layouts that maximize the efficiency and functionality of WiFi modules.

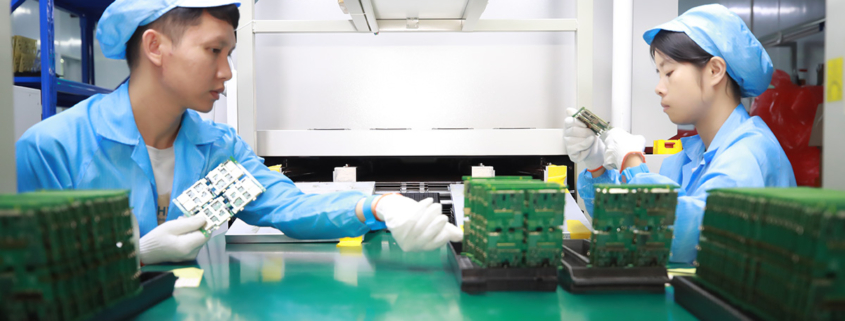

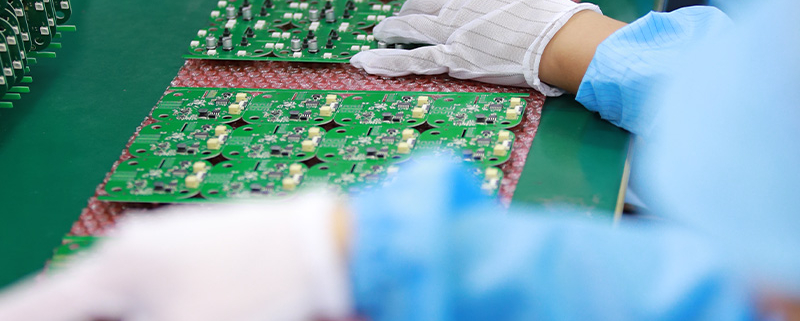

State-of-the-Art Manufacturing Facilities

Our factory in China is equipped with cutting-edge machinery and technology, enabling us to produce high-quality PCBs with exceptional accuracy. Our manufacturing processes adhere to stringent quality standards, ensuring the reliability of every product.

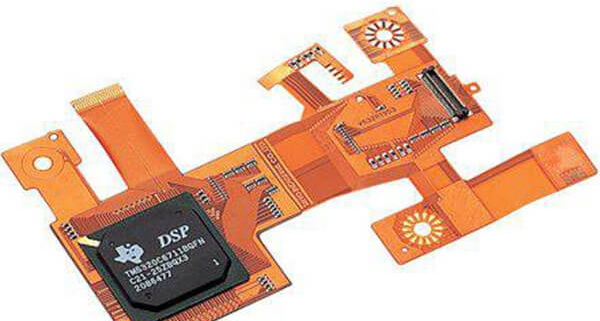

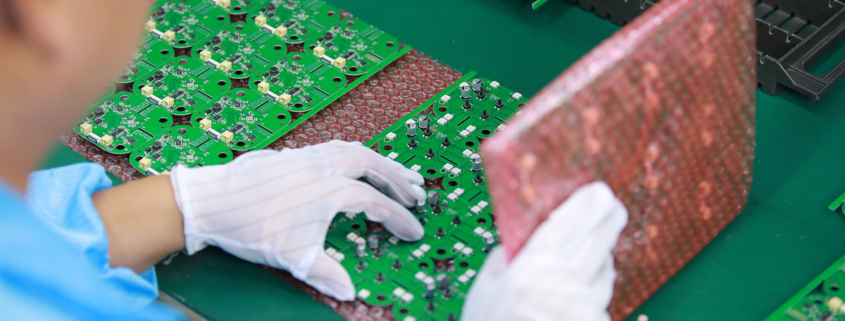

Multi-Layer PCB Production

MTI specializes in multi-layer PCB production, essential for integrating complex WiFi wireless modules into advanced designs. Our expertise ensures that these layers are perfectly aligned and interconnected, enhancing the overall performance of the PCB.

Benefits of Partnering with MTI

Comprehensive OEM/ODM Services

MTI offers comprehensive OEM/ODM services, providing end-to-end solutions from design to manufacturing. This ensures that our clients receive fully customized PCBs that meet their exact specifications.

Tailored Solutions for Diverse Needs

Our team works closely with clients to develop tailored solutions that address their unique challenges. From initial design to final production, we ensure that every aspect of the project is optimized for success.

Reliable Supply Chain and Support

We maintain a reliable supply chain, ensuring timely delivery of high-quality materials and components. Our dedicated support team is always available to assist with any queries or issues, providing exceptional customer service.

Strategic Partnerships

By establishing strategic partnerships with key suppliers and agents, we ensure a steady supply of top-quality components. This reliability is a significant advantage for our clients, enabling them to meet tight deadlines and production schedules.

Quality Assurance and Testing

MTI implements rigorous quality assurance and testing procedures at every stage of manufacturing. This ensures that our PCBs meet the highest standards of performance and reliability.

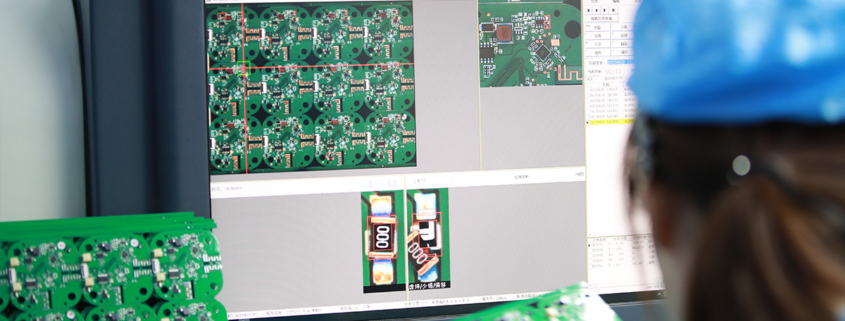

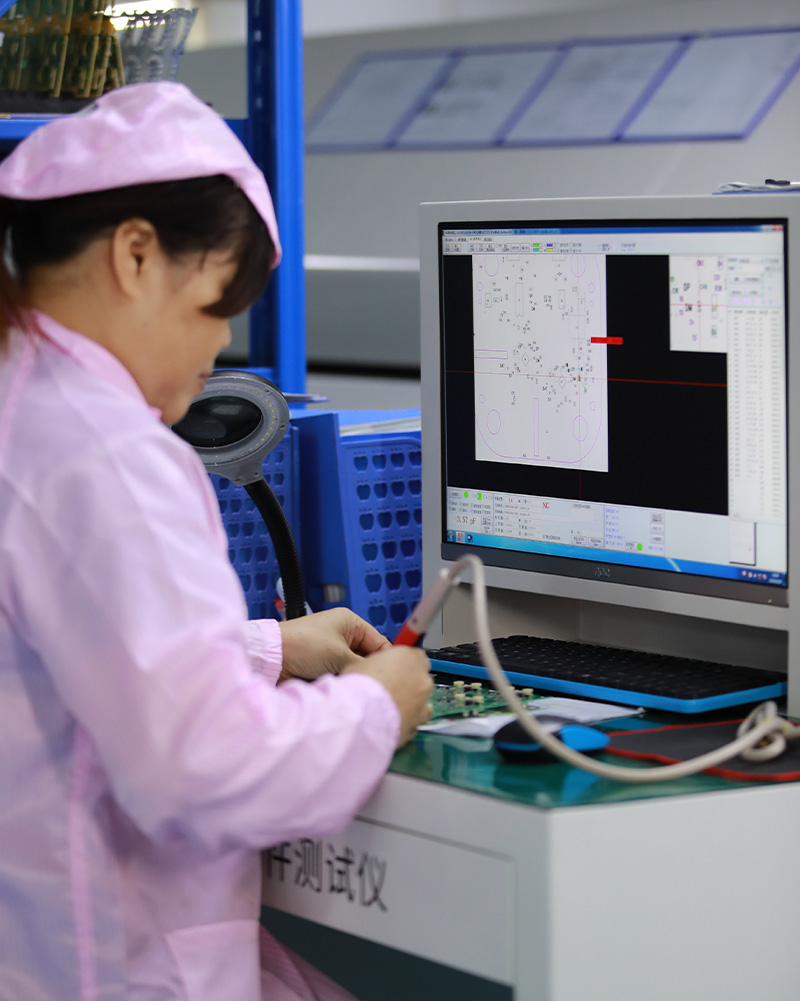

Automated Optical Inspection (AOI)

We use Automated Optical Inspection (AOI) technology to detect and rectify any defects in the PCB layout. This advanced testing method guarantees the accuracy and quality of our products.

Applications of WiFi Wireless Modules with MTI PCBs

Internet of Things (IoT) Devices

WiFi wireless modules are widely used in IoT devices due to their connectivity and low power consumption. MTI’s expertly designed PCBs enhance the functionality and reliability of these devices, making them suitable for various IoT applications.

Smart Home Systems

Our PCBs with WiFi modules are perfect for smart home systems, providing reliable wireless communication for devices such as smart thermostats, security cameras, and lighting controls.

Industrial Automation

In industrial automation, WiFi modules enable efficient wireless control and monitoring. MTI’s robust PCBs ensure the durability and performance required in demanding industrial environments.

Remote Monitoring Systems

Our PCBs are ideal for remote monitoring systems, allowing for seamless data transmission and real-time monitoring of industrial processes.

Conclusion

MTI’s expertise in PCB manufacturing, combined with the advanced capabilities of WiFi wireless modules, offers unparalleled advantages for your projects. Our commitment to quality, innovation, and customer satisfaction makes us the preferred partner for PCB solutions. Enhance connectivity with MTI’s high-performance PCBs and experience the benefits of superior technology and reliable support. Partner with us today to take your projects to the next level.

Tags: PCB Assembly,PCB Bog,SCHEMATIC DESIGN,PCB LAYOUT,FIRMWARE DEVELOPMENT,SMT,PCB TPH Assembly,Box Build Assembly,NPI PCBA PROTOTYPE,