High-Precision PCBA Prototypes for Engineering

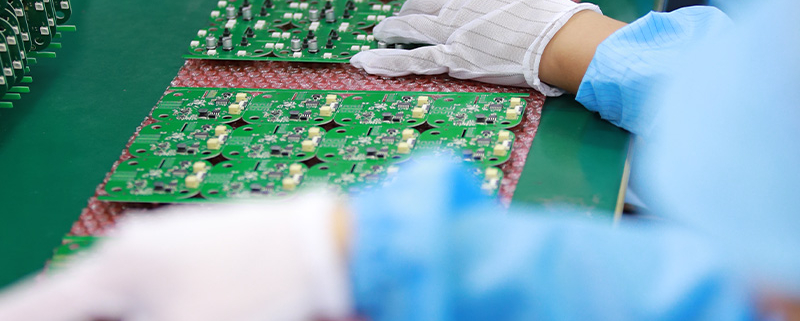

In the fast-evolving world of electronics, the demand for high-precision printed circuit board assemblies (PCBA) is ever-increasing. MTI, a leading PCBA manufacturer, specializes in providing top-tier prototypes that meet the stringent requirements of engineering projects. This article explores the features, benefits, and applications of MTI’s high-precision PCBA prototypes, highlighting their commitment to quality, innovation, and cost performance.

1. Introduction to High-Precision PCBA Prototypes

What is a High-Precision PCBA?

A high-precision PCBA refers to a printed circuit board assembly that is manufactured with exacting standards to ensure optimal performance and reliability. These prototypes are crucial in the early stages of product development, allowing engineers to test and refine their designs before full-scale production.

Key Components:

– Advanced Materials: High-quality substrates and components that ensure durability and performance.

– Precision Manufacturing: Cutting-edge manufacturing processes that achieve tight tolerances and intricate designs.

2. Features of MTI’s High-Precision PCBA Prototypes

State-of-the-Art Manufacturing:

– Advanced Equipment: Utilization of the latest manufacturing technologies, including automated pick-and-place machines and high-resolution imaging.

– Precision Soldering: Accurate soldering techniques ensure reliable connections and long-term durability.

Comprehensive Testing:

– Functional Testing: Each prototype undergoes rigorous functional testing to ensure it meets specified performance criteria.

– Environmental Testing: Prototypes are tested under various environmental conditions to ensure reliability in real-world applications.

Customization and Flexibility:

– Tailored Solutions: MTI offers customized PCBA prototypes to meet specific project requirements, providing flexibility in design and function.

– Rapid Prototyping: Efficient manufacturing processes enable quick turnaround times, allowing engineers to expedite their development cycles.

3. Benefits of MTI’s High-Precision PCBA Prototypes

Enhanced Performance:

– Reliability: High-precision manufacturing ensures that prototypes perform reliably under various conditions.

– Accuracy: Tight tolerances and meticulous assembly result in high-accuracy prototypes, essential for advanced engineering projects.

Cost Performance:

– Competitive Pricing: MTI’s efficient manufacturing and strategic location in China enable them to offer high-quality prototypes at competitive prices.

– Value for Money: Investing in high-precision prototypes reduces the risk of costly design errors, providing long-term cost savings.

Innovation and Quality:

– Continuous R&D: MTI’s ongoing research and development efforts ensure that their products incorporate the latest technological advancements.

– Quality Assurance: Stringent quality control measures are implemented throughout the manufacturing process to maintain the highest standards.

4. Applications of High-Precision PCBA Prototypes

Consumer Electronics:

– Product Development: Essential for developing new consumer electronics, from smartphones to wearable devices.

– Functional Testing: Allows for thorough testing and validation of electronic circuits before mass production.

Medical Devices:

– Prototyping Medical Electronics: Crucial for developing high-precision medical devices that require reliable and accurate performance.

– Compliance Testing: Ensures that prototypes meet stringent regulatory standards for medical equipment.

Automotive Industry:

– Advanced Electronics: Used in the development of automotive electronic systems, including engine control units and infotainment systems.

– Safety Systems: Prototypes for critical safety systems such as airbag controllers and braking systems.

5. Why Choose MTI for High-Precision PCBA Prototypes

Expertise and Innovation:

– MTI’s extensive experience and continuous innovation in PCBA manufacturing ensure the highest standards of quality and performance.

Customization and Flexibility:

– As an OEM/ODM partner, MTI provides customized solutions tailored to specific engineering requirements, ensuring optimal performance and satisfaction.

Reliable Supply Chain:

– MTI collaborates with trusted suppliers and distributors to ensure consistent quality and timely delivery of PCBA prototypes.

Global Reach:

– With a factory based in China, MTI leverages its strategic location to offer high-quality products at competitive prices to clients worldwide.

Conclusion

High-precision PCBA prototypes are essential for advancing engineering projects and ensuring successful product development. MTI, a leading PCBA manufacturer, offers state-of-the-art prototypes that meet the highest standards of accuracy, reliability, and cost performance. By integrating advanced manufacturing techniques, comprehensive testing, and customized solutions, MTI sets the benchmark in the industry. For top-tier PCBA prototypes, trust MTI, your reliable partner in electronics manufacturing.

Tags: PCB Manufacturing,PCB Assemblies,Wire Harness, PCBA Supply Chain Management,FIRMWARE DEVELOPMENT,SMT,PCB TPH Assembly,Box Build Assembly,NPI PCBA PROTOTYPE