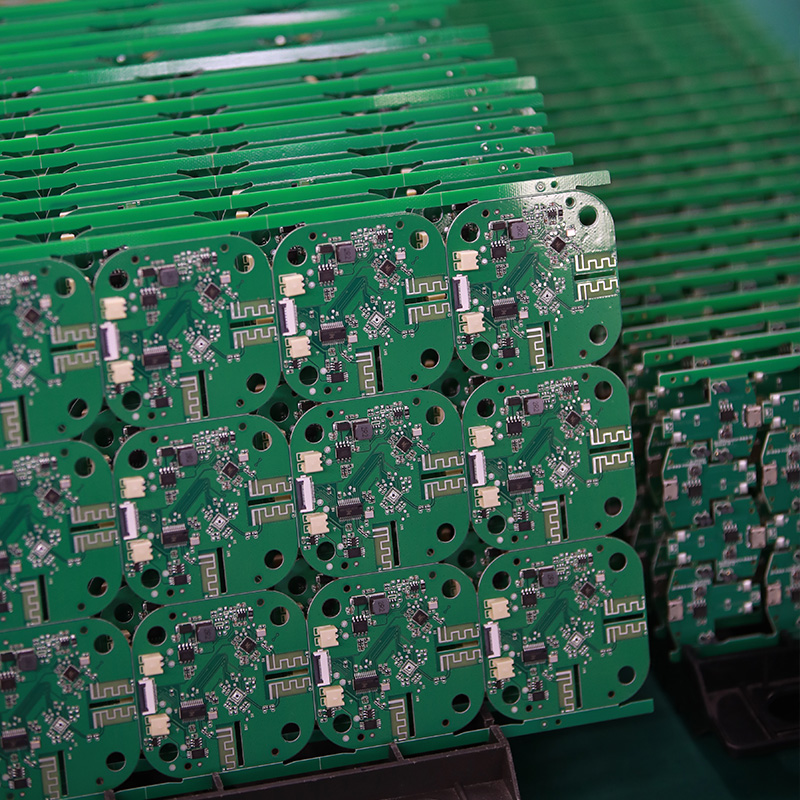

100 keyboard pcb

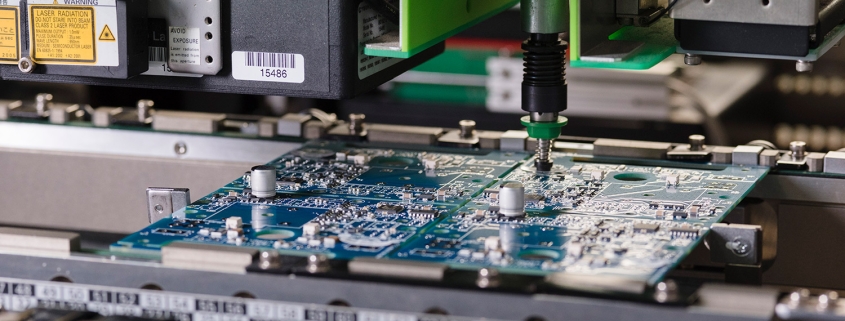

MTI is a professional manufacturer of PCB and PCBA , we supply one-stop service. The company’s main services include PCB production, PCB Assembly and electronic materials purchasing, SMT patch, circuit board welding, circuit board plug-in.

Our clientele spans across major continents (Asia,Europe,Africa,America,Oceania)and encompasses various industries, including healthcare,military

| Product name | 100 keyboard pcb |

| Keyword | assembling circuit boards,flex pcba flexible pcb,pcb manufacturers,1 oz pcb,100w amplifier pcb |

| Place of Origin | China |

| Board Thickness | 2~3.2mm |

| Applicable Industries | military, etc. |

| Service | OEM/ODM manufacturing |

| Certificate | ISO-9001:2015, ISO-14001:2015,ISO-13485:2012.UL/CSA |

| Solder Mask Color | Green |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Belgium,Clipperton Island,Niue,Afghanistan,Greenland,Bolivia,Guernsey,Egypt |

Your deliverables are always ahead of schedule and of the highest quality.

One of our Hardware Design Services is small-batch manufacturing, which allows you to test your idea quickly and verify the functionality of the hardware design and PCB board.

We have rich experience engineer to create a layout using a software platform like Altium Designer. This layout shows you the exact appearance and placement of the components on your board.

FAQs Guide

2.How does the type of PCB finish affect its durability and lifespan?

3.How does the type of laminate material used impact the PCB design?

4.What are the key features of a PCB?

5.What are the differences between a prototype and production PCB?

6.What is the maximum current a PCB can handle?

7.Can PCBs be designed to withstand high vibration or shock?

1.What are the advantages and disadvantages of using a rigid or flexible PCB?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Advantages of rigid PCB:

1. Durability: Rigid PCBs are more durable and can withstand higher levels of stress and strain compared to flexible PCBs.

2. Better for high-speed applications: Rigid PCBs are better suited for high-speed applications as they have better signal integrity and lower signal loss.

3. Cost-effective: Rigid PCBs are generally less expensive to manufacture compared to flexible PCBs.

4. Easier to assemble: Rigid PCBs are easier to assemble and can be used with automated assembly processes, making them more efficient for mass production.

5. Higher component density: Rigid PCBs can accommodate a higher number of components and have a higher component density compared to flexible PCBs.

Disadvantages of rigid PCB:

1. Limited flexibility: Rigid PCBs are not flexible and cannot be bent or twisted, making them unsuitable for certain applications.

2. Bulkier: Rigid PCBs are bulkier and take up more space compared to flexible PCBs, which can be a disadvantage in compact electronic devices.

3. Prone to damage: Rigid PCBs are more prone to damage from vibrations and shocks, which can affect their performance.

Advantages of flexible PCB:

1. Flexibility: Flexible PCBs can be bent, twisted, and folded, making them suitable for applications where space is limited or where the PCB needs to conform to a specific shape.

2. Lightweight: Flexible PCBs are lightweight and take up less space compared to rigid PCBs, making them ideal for portable electronic devices.

3. Better for high vibration environments: Flexible PCBs are more resistant to vibrations and shocks, making them suitable for use in high vibration environments.

4. Higher reliability: Flexible PCBs have fewer interconnects and solder joints, reducing the chances of failure and increasing reliability.

Disadvantages of flexible PCB:

1. Higher cost: Flexible PCBs are generally more expensive to manufacture compared to rigid PCBs.

2. Limited component density: Flexible PCBs have a lower component density compared to rigid PCBs, which can limit their use in high-density applications.

3. Difficult to repair: Flexible PCBs are more difficult to repair compared to rigid PCBs, as they require specialized equipment and expertise.

4. Less suitable for high-speed applications: Flexible PCBs have higher signal loss and lower signal integrity compared to rigid PCBs, making them less suitable for high-speed applications.

2.How does the type of PCB finish affect its durability and lifespan?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

The type of PCB finish can have a significant impact on the durability and lifespan of a PCB. The finish is the final coating applied to the surface of the PCB to protect it from environmental factors and ensure proper functionality. Some common types of PCB finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

1. HASL (Hot Air Solder Leveling):

HASL is a popular and cost-effective finish that involves coating the PCB with a layer of molten solder and then leveling it with hot air. This finish provides good solderability and is suitable for most applications. However, it is not very durable and can be prone to oxidation, which can affect the performance of the PCB over time. HASL finish also has a limited shelf life and may require rework after a certain period.

2. ENIG (Electroless Nickel Immersion Gold):

ENIG is a more advanced and durable finish compared to HASL. It involves depositing a layer of nickel and then a layer of gold on the surface of the PCB. This finish provides excellent corrosion resistance and is suitable for high-reliability applications. ENIG finish also has a longer shelf life and does not require rework as frequently as HASL.

3. OSP (Organic Solderability Preservative):

OSP is a thin organic coating applied to the surface of the PCB to protect it from oxidation. It is a cost-effective finish and provides good solderability. However, OSP finish is not as durable as ENIG and may require rework after a certain period. It is also not suitable for high-temperature applications.

In summary, the type of PCB finish can affect its durability and lifespan in the following ways:

– Corrosion resistance: Finishes like ENIG and OSP provide better corrosion resistance compared to HASL, which can affect the performance and lifespan of the PCB.

– Shelf life: Finishes like ENIG have a longer shelf life compared to HASL, which may require rework after a certain period.

– Solderability: All finishes provide good solderability, but ENIG and OSP are more suitable for high-reliability applications.

– Environmental factors: The type of finish can also affect the PCB’s resistance to environmental factors like humidity, temperature, and chemicals, which can impact its durability and lifespan.

In conclusion, choosing the right type of PCB finish is crucial for ensuring the durability and longevity of the PCB. Factors such as the application, environmental conditions, and budget should be considered when selecting the appropriate finish for a PCB.

3.How does the type of laminate material used impact the PCB design?

As one of the top 100 keyboard pcb manufacturers in China, we take this very seriously.

The type of laminate material used can impact the PCB design in several ways:

1. Electrical properties: Different laminate materials have different electrical properties, such as dielectric constant, loss tangent, and insulation resistance. These properties can affect the signal integrity and impedance of the PCB, which can impact the performance of the circuit.

2. Thermal properties: Some laminate materials have better thermal conductivity than others, which can affect the heat dissipation of the PCB. This is especially important for high-power applications where heat management is crucial.

3. Mechanical properties: The mechanical properties of the laminate material, such as stiffness and flexibility, can impact the overall durability and reliability of the PCB. This is important for applications where the PCB may be subjected to physical stress or vibration.

4. Cost: Different laminate materials have different costs, which can impact the overall cost of the PCB. Some materials may be more expensive but offer better performance, while others may be more cost-effective but have lower performance.

5. Manufacturing process: The type of laminate material used can also impact the manufacturing process of the PCB. Some materials may require specialized equipment or processes, which can affect the production time and cost.

6. Compatibility with components: Certain laminate materials may not be compatible with certain components, such as high-frequency components or components that require specific soldering temperatures. This can limit the design options and affect the functionality of the PCB.

Overall, the type of laminate material used can significantly impact the design, performance, and cost of a PCB. It is important to carefully consider the requirements of the circuit and choose a suitable laminate material to ensure optimal performance and reliability.

4.What are the key features of a PCB?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

1. Substrate: The base material on which the circuit is printed, usually made of fiberglass or composite epoxy.

2. Conductive Traces: Thin copper lines that connect the components on the PCB.

3. Pads: Small copper areas on the PCB surface where components are soldered.

4. Vias: Holes drilled through the PCB to connect the different layers of the circuit.

5. Solder Mask: A layer of protective material that covers the copper traces and pads, preventing accidental short circuits.

6. Silkscreen: A layer of ink that is printed on the PCB to label the components and provide other useful information.

7. Components: Electronic devices such as resistors, capacitors, and integrated circuits that are mounted on the PCB.

8. Mounting Holes: Holes drilled on the PCB to allow it to be securely attached to a larger device or enclosure.

9. Copper Pour: Large areas of copper that are used to provide a common ground or power plane for the circuit.

10. Edge Connectors: Metal contacts on the edge of the PCB that allow it to be connected to other circuits or devices.

11. Solder Bridges: Small areas of exposed copper that allow for the connection of two or more traces.

12. Test Points: Small pads or holes on the PCB that allow for testing and troubleshooting of the circuit.

13. Silkscreen Legend: Printed text or symbols on the silkscreen layer that provide additional information about the PCB and its components.

14. Designators: Letters or numbers printed on the silkscreen layer to identify specific components on the PCB.

15. Reference Designators: A combination of letters and numbers that identify the location of a component on the PCB according to the schematic diagram.

5.What are the differences between a prototype and production PCB?

We have a good reputation and image in the industry. The quality and price advantage of 100 keyboard pcb products is an important factor in our hard overseas market.

1. Purpose: The main difference between a prototype and production PCB is their purpose. A prototype PCB is used for testing and validation of a design, while a production PCB is used for mass production and commercial use.

2. Design: Prototype PCBs are usually hand-soldered and have a simpler design compared to production PCBs. Production PCBs are designed with more precision and complexity to meet the specific requirements of the final product.

3. Materials: Prototype PCBs are often made with cheaper materials such as FR-4, while production PCBs use higher quality materials such as ceramic or metal core for better performance and durability.

4. Quantity: Prototype PCBs are usually made in small quantities, while production PCBs are manufactured in large quantities to meet the demand of the market.

5. Cost: Due to the use of cheaper materials and smaller quantities, prototype PCBs are less expensive compared to production PCBs. Production PCBs require a larger investment due to the use of higher quality materials and larger quantities.

6. Lead time: Prototype PCBs have a shorter lead time as they are made in smaller quantities and can be hand-soldered. Production PCBs have a longer lead time as they require more complex manufacturing processes and larger quantities.

7. Testing: Prototype PCBs are extensively tested to ensure the design is functional and meets the required specifications. Production PCBs also undergo testing, but the focus is more on quality control and consistency in mass production.

8. Documentation: Prototype PCBs may not have detailed documentation as they are often hand-soldered and used for testing purposes. Production PCBs have detailed documentation to ensure consistency in manufacturing and for future reference.

9. Modifications: Prototype PCBs are easier to modify and make changes to, as they are not mass-produced. Production PCBs are more difficult to modify as any changes can affect the entire production process.

10. Reliability: Production PCBs are designed and manufactured to be more reliable and durable, as they will be used in the final product. Prototype PCBs may not have the same level of reliability as they are used for testing and may not undergo the same level of quality control.

6.What is the maximum current a PCB can handle?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The maximum current a PCB can handle depends on various factors such as the thickness and width of the copper traces, the type of material used for the PCB, and the ambient temperature. Generally, a standard PCB can handle currents up to 10-20 amps, while high-power PCBs can handle currents up to 50-100 amps. However, it is always recommended to consult with a PCB manufacturer for specific current handling capabilities for a particular PCB design.

7.Can PCBs be designed to withstand high vibration or shock?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, PCBs can be designed to withstand high vibration or shock by incorporating certain design features and using appropriate materials. Some ways to make a PCB more resistant to vibration and shock include:

1. Using a thicker and more rigid PCB substrate material, such as FR-4 or ceramic, to provide better structural support and reduce flexing.

2. Adding additional support structures, such as mounting holes or stiffeners, to secure the PCB to the chassis or enclosure.

3. Using smaller and more compact components to reduce the overall weight and size of the PCB, which can help minimize the effects of vibration.

4. Using shock-absorbing materials, such as rubber or foam, between the PCB and the mounting surface to absorb and dampen vibrations.

5. Designing the PCB layout to minimize the length and number of traces and vias, which can reduce the risk of mechanical stress and failure.

6. Using surface mount technology (SMT) components instead of through-hole components, as they are less prone to damage from vibration.

7. Incorporating conformal coating or potting materials to protect the PCB and components from moisture and mechanical stress.

It is important to consider the specific requirements and environment in which the PCB will be used when designing for high vibration or shock resistance. Consulting with a PCB design expert can also help ensure that the PCB is properly designed to withstand these conditions.

Tags:12v battery charger pcb board , eft pcb