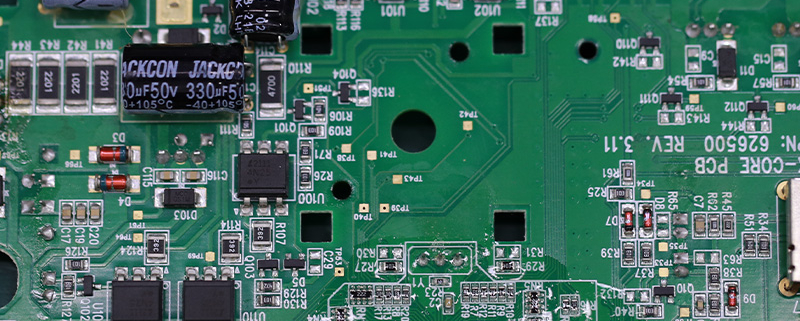

104 pcb

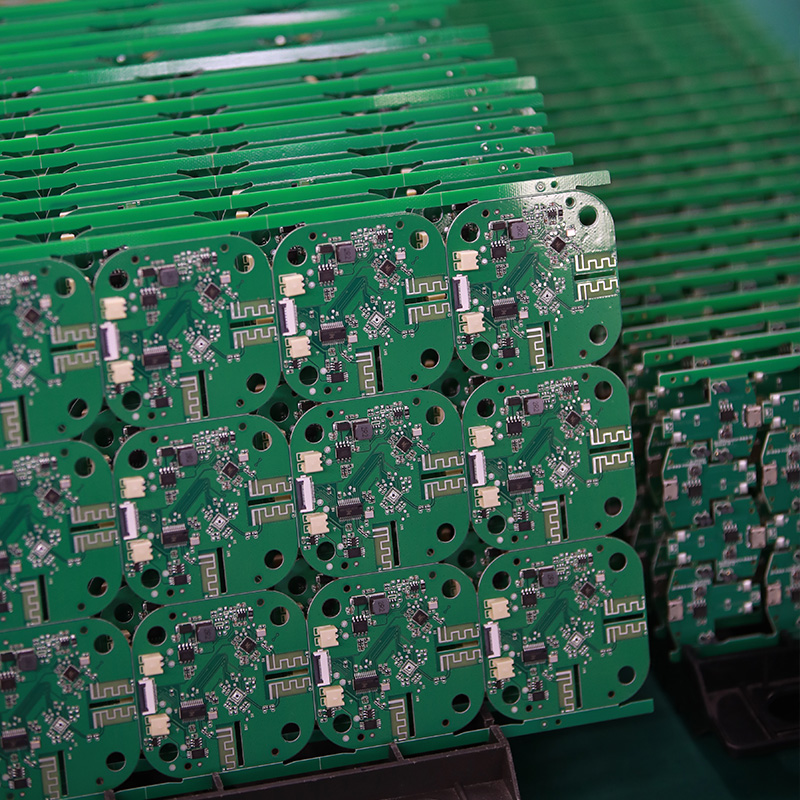

MTI is a professional manufacturer of PCB and PCBA , we supply one-stop service. The company’s main services include PCB production, PCB Assembly and electronic materials purchasing, SMT patch, circuit board welding, circuit board plug-in.

Our clientele spans across major continents (Asia,Europe,Africa,America,Oceania)and encompasses various industries, including healthcare,military

| Product name | 104 pcb |

| Keyword | 2.4 g pcb antenna layout,3080 ftw3 pcb |

| Place of Origin | China |

| Board Thickness | 1~3.2mm |

| Applicable Industries | power supply, etc. |

| Service | OEM/ODM manufacturing |

| Certificate | ISO-9001:2015, ISO-14001:2015,ISO-13485:2012.UL/CSA |

| Solder Mask Color | White |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Tanzania,Malaysia,Dominican Republic,Niue,Lebanon,Ukraine,Bermuda,Seychelles |

One of our Hardware Design Services is small-batch manufacturing, which allows you to test your idea quickly and verify the functionality of the hardware design and PCB board.

We have rich experience engineer to create a layout using a software platform like Altium Designer. This layout shows you the exact appearance and placement of the components on your board.

Your deliverables are always ahead of schedule and of the highest quality.

FAQs Guide

2.Is it possible to have different components on each side of a PCB?

3.How important is the trace width and spacing in a PCB design?

4.Can PCBs have different shapes and sizes?

5.What makes a PCB resistant to environmental factors such as moisture and temperature?

1.How does the type of solder mask used affect the PCB’s performance?

We have broad development space in domestic and foreign markets. 104 pcbs have great advantages in terms of price, quality, and delivery date.

The type of solder mask used can affect the PCB’s performance in several ways:

1. Insulation: Solder mask is used to insulate the copper traces on a PCB, preventing them from coming into contact with each other and causing a short circuit. The type of solder mask used can affect the level of insulation provided, which can impact the overall reliability and functionality of the PCB.

2. Solderability: Solder mask also plays a crucial role in the soldering process. The type of solder mask used can affect the surface tension and wetting properties of the solder, which can impact the quality of the solder joints and the overall reliability of the PCB.

3. Thermal resistance: Solder mask can also act as a thermal barrier, protecting the PCB from excessive heat. The type of solder mask used can affect the thermal resistance of the PCB, which can impact its ability to dissipate heat and its overall thermal performance.

4. Chemical resistance: Solder mask is also exposed to various chemicals during the PCB manufacturing process, such as flux and cleaning agents. The type of solder mask used can affect its resistance to these chemicals, which can impact the overall durability and reliability of the PCB.

5. Electrical properties: The type of solder mask used can also affect the electrical properties of the PCB, such as its dielectric constant and dissipation factor. These properties can impact the performance of high-frequency circuits and signal integrity.

Overall, the type of solder mask used can have a significant impact on the performance, reliability, and durability of a PCB. It is essential to carefully select the appropriate solder mask for a specific application to ensure optimal performance.

2.Is it possible to have different components on each side of a PCB?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Yes, it is possible to have different components on each side of a PCB. This is known as a double-sided PCB or a two-layer PCB. The components on each side can be connected through vias, which are small holes drilled through the PCB that allow for electrical connections between the layers. This allows for more compact and complex circuit designs. However, it also adds complexity to the manufacturing process and may increase the cost of the PCB.

3.How important is the trace width and spacing in a PCB design?

Our 104 pcb products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

The trace width and spacing in a PCB design are crucial factors that can greatly affect the performance and reliability of the circuit. Here are some reasons why:

1. Current carrying capacity: The trace width determines the amount of current that can flow through the trace without causing excessive heating. If the trace width is too narrow, it can lead to overheating and damage to the circuit.

2. Voltage drop: The trace width also affects the voltage drop across the trace. A narrow trace will have a higher resistance, resulting in a higher voltage drop. This can cause a decrease in the voltage level at the end of the trace, affecting the performance of the circuit.

3. Signal integrity: The spacing between traces is critical for maintaining signal integrity. If the spacing is too narrow, it can lead to crosstalk and interference between signals, resulting in errors and malfunctions in the circuit.

4. Thermal management: The spacing between traces also plays a role in thermal management. Adequate spacing between traces allows for better air circulation, which helps dissipate heat from the circuit. This is especially important for high-power circuits.

5. Manufacturing constraints: The trace width and spacing also need to be considered in the manufacturing process. If the traces are too close together, it can be challenging to etch and inspect the PCB, leading to manufacturing defects.

In summary, the trace width and spacing are critical parameters that need to be carefully considered in PCB design to ensure proper functioning and reliability of the circuit.

4.Can PCBs have different shapes and sizes?

Our company has many years of 104 pcb experience and expertise.

Yes, PCBs (printed circuit boards) can have different shapes and sizes depending on the specific design and purpose of the circuit. They can range from small and compact to large and complex, and can be rectangular, circular, or even irregularly shaped. The shape and size of a PCB is determined by the layout of the components and the desired functionality of the circuit.

5.What makes a PCB resistant to environmental factors such as moisture and temperature?

We should perform well in market competition, and the prices of 104 pcb products have a great competitive advantage.

1. Material Selection: The choice of materials used in the PCB can greatly affect its resistance to environmental factors. Materials such as FR-4, polyimide, and ceramic are known for their high resistance to moisture and temperature.

2. Conformal Coating: Applying a conformal coating to the PCB can provide an additional layer of protection against moisture and temperature. This coating acts as a barrier between the PCB and the environment, preventing any moisture or contaminants from reaching the components.

3. Solder Mask: The solder mask used on the PCB can also play a role in its resistance to environmental factors. A high-quality solder mask can provide a protective layer against moisture and temperature, preventing any damage to the components.

4. Component Placement: Proper placement of components on the PCB can also contribute to its resistance to environmental factors. Components that are sensitive to moisture or temperature should be placed away from areas that are prone to these factors, such as near heat sources or in areas with high humidity.

5. Thermal Management: Adequate thermal management is crucial for maintaining the temperature of the PCB within safe limits. This can be achieved through the use of heat sinks, thermal vias, and proper ventilation.

6. Design Considerations: The design of the PCB can also impact its resistance to environmental factors. Factors such as trace width, spacing, and routing can affect the PCB’s ability to withstand temperature changes and moisture exposure.

7. Testing and Quality Control: Proper testing and quality control measures can ensure that the PCB is built to withstand environmental factors. This includes testing for moisture resistance, thermal cycling, and other environmental stressors.

8. Compliance with Standards: Following industry standards and regulations for PCB design and manufacturing can also contribute to its resistance to environmental factors. These standards often include guidelines for material selection, component placement, and testing procedures.

Tags:h60 pcb,pcb assembling,circuit card assemblies