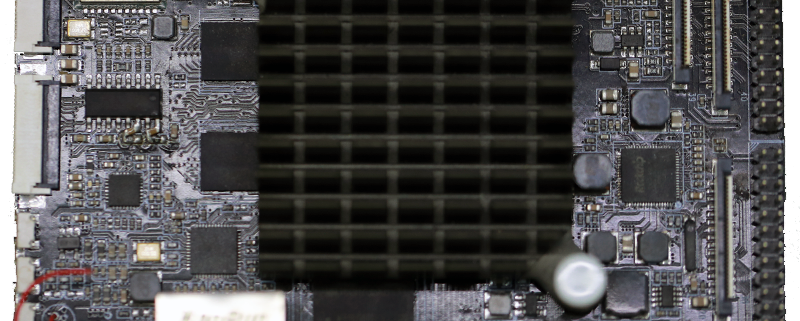

12 layer pcb stack up

MTI is a manufacturer of high-precision printed circuit board (PCB).We specialize in the manufacture of high precision double-sided and multilayer printed circuit boards, We provide high quality products and faster service for high-tech companies.

We have a group of experienced staff and high-quality management team, set up a complete quality assurance system. Products include FR-4 PCB, Metal PCB and RFPCB (ceramic PCB, PTFE PCB), etc. Have rich experience in the production of thick copper PCB, RF PCB, high Tg PCB, HDI PCB.With ISO9001, ISO14001, TS16949, ISO 13485, RoHS certifications.

| Product name | 12 layer pcb stack up |

| Keyword | 1.6 mm pcb,1 oz pcb thickness,108 key keyboard pcb,pcb fab |

| Place of Origin | China |

| Board Thickness | 2~3.2mm |

| Applicable Industries | military, etc. |

| Service | OEM/ODM manufacturing |

| Certificate | ISO-9001:2015, ISO-14001:2015,ISO-13485:2012.UL/CSA |

| Solder Mask Color | Blue |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Haiti,Luxembourg,Tonga,Namibia,Niger,Grenada,Cook Islands,French Guiana |

We have rich experience engineer to create a layout using a software platform like Altium Designer. This layout shows you the exact appearance and placement of the components on your board.

Your deliverables are always ahead of schedule and of the highest quality.

One of our Hardware Design Services is small-batch manufacturing, which allows you to test your idea quickly and verify the functionality of the hardware design and PCB board.

FAQs Guide

2.What is testability in PCB design and how is it achieved?

3.How important is the trace width and spacing in a PCB design?

4.How does the type of surface finish on a PCB affect its performance?

5.What are the advantages and disadvantages of using a rigid or flexible PCB?

1.How do surface mount components differ from through-hole components in a PCB?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

Surface mount components (SMD) and through-hole components (THD) are two different types of electronic components used in printed circuit boards (PCBs). The main difference between them lies in their method of mounting onto the PCB.

1. Mounting Method:

The main difference between SMD and THD components is their mounting method. SMD components are mounted directly onto the surface of the PCB, while THD components are inserted into holes drilled into the PCB and soldered on the other side.

2. Size:

SMD components are generally smaller in size compared to THD components. This is because SMD components do not require leads or pins for mounting, allowing for a more compact design. THD components, on the other hand, have leads or pins that need to be inserted into the PCB, making them larger in size.

3. Space Efficiency:

Due to their smaller size, SMD components allow for a more space-efficient design on the PCB. This is especially important in modern electronic devices where space is limited. THD components take up more space on the PCB due to their larger size and the need for holes to be drilled.

4. Cost:

SMD components are generally more expensive than THD components. This is because SMD components require more advanced manufacturing techniques and equipment, making them costlier to produce.

5. Assembly Process:

The assembly process for SMD components is automated, using pick-and-place machines to accurately place the components onto the PCB. This makes the process faster and more efficient compared to THD components, which require manual insertion and soldering.

6. Electrical Performance:

SMD components have better electrical performance compared to THD components. This is because SMD components have shorter leads, resulting in less parasitic capacitance and inductance, leading to better signal integrity.

In summary, SMD components offer a more compact design, better electrical performance, and a faster assembly process, but at a higher cost. THD components, on the other hand, are larger in size, less expensive, and can handle higher power and voltage ratings. The choice between SMD and THD components depends on the specific requirements of the PCB design and the intended use of the electronic device.

2.What is testability in PCB design and how is it achieved?

Our 12 layer pcb stack up products undergo strict quality control to ensure customer satisfaction.

Testability in PCB design refers to the ease and accuracy with which a printed circuit board (PCB) can be tested for functionality and performance. It is an important aspect of PCB design as it ensures that any defects or issues with the board can be identified and addressed before it is put into use.

Achieving testability in PCB design involves implementing certain design features and techniques that make it easier to test the board. These include:

1. Design for Test (DFT): This involves designing the PCB with specific test points and access points that allow for easy and accurate testing of different components and circuits.

2. Test Points: These are designated points on the PCB where test probes can be connected to measure voltage, current, and other parameters. Test points should be strategically placed to provide access to critical components and circuits.

3. Test Pads: These are small copper pads on the PCB that are used for attaching test probes. They should be placed close to the corresponding component or circuit for accurate testing.

4. Test Jigs: These are specialized tools used for testing PCBs. They can be custom-made for a specific PCB design and can greatly improve the accuracy and efficiency of testing.

5. Design for Manufacturability (DFM): This involves designing the PCB with manufacturing and testing in mind. This includes using standard components, avoiding complex layouts, and minimizing the number of layers to make testing easier.

6. Design for Debug (DFD): This involves designing the PCB with features that make it easier to identify and troubleshoot any issues that may arise during testing.

Overall, achieving testability in PCB design requires careful planning and consideration of the testing process. By implementing DFT, using test points and pads, and designing for manufacturability and debug, designers can ensure that their PCBs are easily testable and can be quickly and accurately diagnosed for any potential issues.

3.How important is the trace width and spacing in a PCB design?

Our 12 layer pcb stack up products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

The trace width and spacing in a PCB design are crucial factors that can greatly affect the performance and reliability of the circuit. Here are some reasons why:

1. Current carrying capacity: The trace width determines the amount of current that can flow through the trace without causing excessive heating. If the trace width is too narrow, it can lead to overheating and damage to the circuit.

2. Voltage drop: The trace width also affects the voltage drop across the trace. A narrow trace will have a higher resistance, resulting in a higher voltage drop. This can cause a decrease in the voltage level at the end of the trace, affecting the performance of the circuit.

3. Signal integrity: The spacing between traces is critical for maintaining signal integrity. If the spacing is too narrow, it can lead to crosstalk and interference between signals, resulting in errors and malfunctions in the circuit.

4. Thermal management: The spacing between traces also plays a role in thermal management. Adequate spacing between traces allows for better air circulation, which helps dissipate heat from the circuit. This is especially important for high-power circuits.

5. Manufacturing constraints: The trace width and spacing also need to be considered in the manufacturing process. If the traces are too close together, it can be challenging to etch and inspect the PCB, leading to manufacturing defects.

In summary, the trace width and spacing are critical parameters that need to be carefully considered in PCB design to ensure proper functioning and reliability of the circuit.

4.How does the type of surface finish on a PCB affect its performance?

12 layer pcb stack up is not a product only, but also can help you comes to money-making.

The type of surface finish on a PCB can affect its performance in several ways:

1. Electrical Performance: The surface finish can impact the electrical properties of the PCB, such as impedance, signal integrity, and resistance. A smooth and uniform surface finish can help maintain consistent electrical properties, while a rough or uneven finish can cause signal loss and interference.

2. Solderability: The surface finish plays a crucial role in the solderability of the PCB. A good surface finish should provide a flat and even surface for the components to be soldered onto. A poor surface finish can result in solder defects, such as bridging, voids, and poor wetting, which can affect the reliability of the PCB.

3. Corrosion Resistance: The surface finish can also affect the corrosion resistance of the PCB. A high-quality surface finish can protect the copper traces from oxidation and other environmental factors, ensuring the long-term reliability of the PCB.

4. Assembly Process: Different surface finishes may require different assembly processes, such as the type of solder used or the temperature and time required for reflow. This can affect the overall efficiency and cost of the PCB assembly process.

5. Cost: The type of surface finish can also impact the cost of the PCB. Some surface finishes, such as gold plating, are more expensive than others, such as HASL (Hot Air Solder Leveling). Choosing the right surface finish can help balance the cost and performance requirements of the PCB.

Overall, the surface finish on a PCB can significantly impact its performance, reliability, and cost. It is essential to carefully consider the requirements and choose the most suitable surface finish for the specific application.

5.What are the advantages and disadvantages of using a rigid or flexible PCB?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Advantages of rigid PCB:

1. Durability: Rigid PCBs are more durable and can withstand higher levels of stress and strain compared to flexible PCBs.

2. Better for high-speed applications: Rigid PCBs are better suited for high-speed applications as they have better signal integrity and lower signal loss.

3. Cost-effective: Rigid PCBs are generally less expensive to manufacture compared to flexible PCBs.

4. Easier to assemble: Rigid PCBs are easier to assemble and can be used with automated assembly processes, making them more efficient for mass production.

5. Higher component density: Rigid PCBs can accommodate a higher number of components and have a higher component density compared to flexible PCBs.

Disadvantages of rigid PCB:

1. Limited flexibility: Rigid PCBs are not flexible and cannot be bent or twisted, making them unsuitable for certain applications.

2. Bulkier: Rigid PCBs are bulkier and take up more space compared to flexible PCBs, which can be a disadvantage in compact electronic devices.

3. Prone to damage: Rigid PCBs are more prone to damage from vibrations and shocks, which can affect their performance.

Advantages of flexible PCB:

1. Flexibility: Flexible PCBs can be bent, twisted, and folded, making them suitable for applications where space is limited or where the PCB needs to conform to a specific shape.

2. Lightweight: Flexible PCBs are lightweight and take up less space compared to rigid PCBs, making them ideal for portable electronic devices.

3. Better for high vibration environments: Flexible PCBs are more resistant to vibrations and shocks, making them suitable for use in high vibration environments.

4. Higher reliability: Flexible PCBs have fewer interconnects and solder joints, reducing the chances of failure and increasing reliability.

Disadvantages of flexible PCB:

1. Higher cost: Flexible PCBs are generally more expensive to manufacture compared to rigid PCBs.

2. Limited component density: Flexible PCBs have a lower component density compared to rigid PCBs, which can limit their use in high-density applications.

3. Difficult to repair: Flexible PCBs are more difficult to repair compared to rigid PCBs, as they require specialized equipment and expertise.

4. Less suitable for high-speed applications: Flexible PCBs have higher signal loss and lower signal integrity compared to rigid PCBs, making them less suitable for high-speed applications.

Tags:enig pcb,1 layer vs 2 layer pcb,circuit card assembly manufacturing process,flex pcba manufacturer