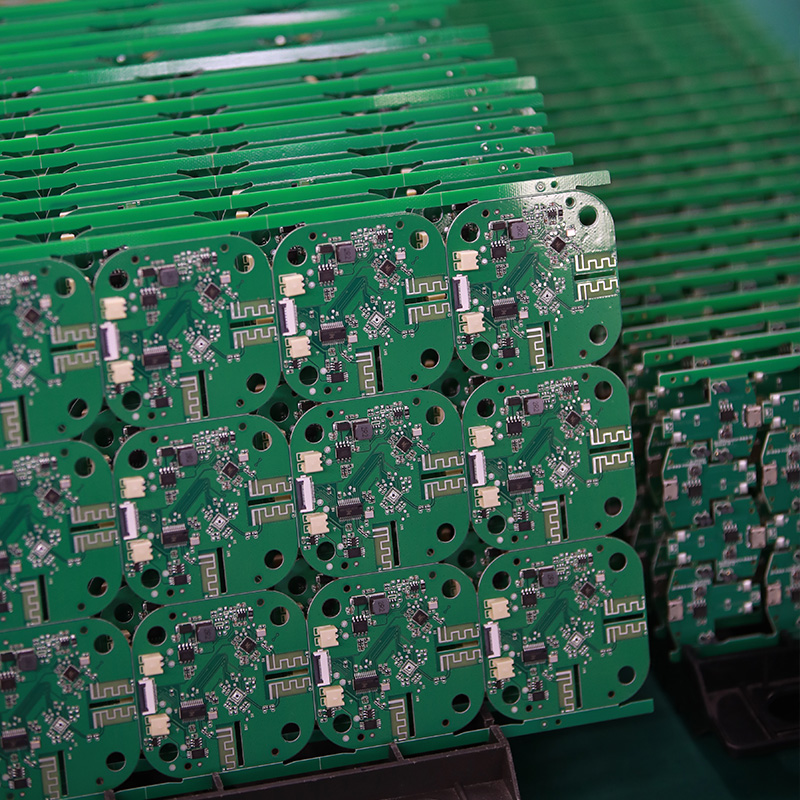

1 layer vs 2 layer pcb

For over two decades, MTI has been dedicated to providing comprehensive OEM/ODM manufacturing services to customers worldwide. With our extensive expertise in PCB assembly, we have established strong collaborative relationships with authorized component distributors. This allows us to source any required components at competitive prices, ensuring cost-effectiveness for our clients.

| Product name | 1 layer vs 2 layer pcb |

| Keyword | rigid flex electronic pcba,1000w amplifier pcb board,108 keyboard pcb,china rigid flex electronic pcba,100 mechanical keyboard pcb |

| Place of Origin | China |

| Board Thickness | 2~3.2mm |

| Applicable Industries | security, etc. |

| Service | OEM/ODM manufacturing |

| Certificate | ISO-9001:2015, ISO-14001:2015,ISO-13485:2012.UL/CSA |

| Solder Mask Color | Blue |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:New Caledonia,Sierra Leone,Antarctica,Benin,Armenia,Tonga |

Your deliverables are always ahead of schedule and of the highest quality.

One of our Hardware Design Services is small-batch manufacturing, which allows you to test your idea quickly and verify the functionality of the hardware design and PCB board.

We have rich experience engineer to create a layout using a software platform like Altium Designer. This layout shows you the exact appearance and placement of the components on your board.

FAQs Guide

2.What is the minimum distance required between components on a PCB?

3.Can PCBs be made with different thicknesses?

4.Can PCBs be designed to withstand high vibration or shock?

5.How do surface mount components differ from through-hole components in a PCB?

6.What materials are commonly used to make PCBs?

1.What are the key features of a PCB?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

1. Substrate: The base material on which the circuit is printed, usually made of fiberglass or composite epoxy.

2. Conductive Traces: Thin copper lines that connect the components on the PCB.

3. Pads: Small copper areas on the PCB surface where components are soldered.

4. Vias: Holes drilled through the PCB to connect the different layers of the circuit.

5. Solder Mask: A layer of protective material that covers the copper traces and pads, preventing accidental short circuits.

6. Silkscreen: A layer of ink that is printed on the PCB to label the components and provide other useful information.

7. Components: Electronic devices such as resistors, capacitors, and integrated circuits that are mounted on the PCB.

8. Mounting Holes: Holes drilled on the PCB to allow it to be securely attached to a larger device or enclosure.

9. Copper Pour: Large areas of copper that are used to provide a common ground or power plane for the circuit.

10. Edge Connectors: Metal contacts on the edge of the PCB that allow it to be connected to other circuits or devices.

11. Solder Bridges: Small areas of exposed copper that allow for the connection of two or more traces.

12. Test Points: Small pads or holes on the PCB that allow for testing and troubleshooting of the circuit.

13. Silkscreen Legend: Printed text or symbols on the silkscreen layer that provide additional information about the PCB and its components.

14. Designators: Letters or numbers printed on the silkscreen layer to identify specific components on the PCB.

15. Reference Designators: A combination of letters and numbers that identify the location of a component on the PCB according to the schematic diagram.

2.What is the minimum distance required between components on a PCB?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 1 layer vs 2 layer pcb products.

The minimum distance required between components on a PCB depends on various factors such as the type of components, their size, and the manufacturing process used. Generally, the minimum distance between components is determined by the manufacturer’s design rules and guidelines.

For surface mount components, the minimum distance between components is typically 0.2mm to 0.3mm. This distance is necessary to ensure that the solder paste does not bridge between the pads during the reflow process.

For through-hole components, the minimum distance between components is typically 1mm to 2mm. This distance is necessary to ensure that the components do not interfere with each other during the assembly process.

In high-speed and high-frequency applications, the minimum distance between components may need to be increased to avoid signal interference and crosstalk. In these cases, the manufacturer’s design rules and guidelines should be followed closely.

Overall, the minimum distance between components on a PCB should be determined based on the specific requirements of the design and the capabilities of the manufacturing process.

3.Can PCBs be made with different thicknesses?

We operate our 1 layer vs 2 layer pcb business with integrity and honesty.

Yes, PCBs (printed circuit boards) can be made with different thicknesses. The thickness of a PCB is determined by the thickness of the copper layer and the thickness of the substrate material. The copper layer thickness can range from 0.5 oz to 3 oz, while the substrate material thickness can range from 0.2 mm to 3.2 mm. The most common thicknesses for PCBs are 1.6 mm and 0.8 mm, but custom thicknesses can be requested from PCB manufacturers. The thickness of a PCB can affect its mechanical strength, thermal properties, and electrical performance.

4.Can PCBs be designed to withstand high vibration or shock?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, PCBs can be designed to withstand high vibration or shock by incorporating certain design features and using appropriate materials. Some ways to make a PCB more resistant to vibration and shock include:

1. Using a thicker and more rigid PCB substrate material, such as FR-4 or ceramic, to provide better structural support and reduce flexing.

2. Adding additional support structures, such as mounting holes or stiffeners, to secure the PCB to the chassis or enclosure.

3. Using smaller and more compact components to reduce the overall weight and size of the PCB, which can help minimize the effects of vibration.

4. Using shock-absorbing materials, such as rubber or foam, between the PCB and the mounting surface to absorb and dampen vibrations.

5. Designing the PCB layout to minimize the length and number of traces and vias, which can reduce the risk of mechanical stress and failure.

6. Using surface mount technology (SMT) components instead of through-hole components, as they are less prone to damage from vibration.

7. Incorporating conformal coating or potting materials to protect the PCB and components from moisture and mechanical stress.

It is important to consider the specific requirements and environment in which the PCB will be used when designing for high vibration or shock resistance. Consulting with a PCB design expert can also help ensure that the PCB is properly designed to withstand these conditions.

5.How do surface mount components differ from through-hole components in a PCB?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

Surface mount components (SMD) and through-hole components (THD) are two different types of electronic components used in printed circuit boards (PCBs). The main difference between them lies in their method of mounting onto the PCB.

1. Mounting Method:

The main difference between SMD and THD components is their mounting method. SMD components are mounted directly onto the surface of the PCB, while THD components are inserted into holes drilled into the PCB and soldered on the other side.

2. Size:

SMD components are generally smaller in size compared to THD components. This is because SMD components do not require leads or pins for mounting, allowing for a more compact design. THD components, on the other hand, have leads or pins that need to be inserted into the PCB, making them larger in size.

3. Space Efficiency:

Due to their smaller size, SMD components allow for a more space-efficient design on the PCB. This is especially important in modern electronic devices where space is limited. THD components take up more space on the PCB due to their larger size and the need for holes to be drilled.

4. Cost:

SMD components are generally more expensive than THD components. This is because SMD components require more advanced manufacturing techniques and equipment, making them costlier to produce.

5. Assembly Process:

The assembly process for SMD components is automated, using pick-and-place machines to accurately place the components onto the PCB. This makes the process faster and more efficient compared to THD components, which require manual insertion and soldering.

6. Electrical Performance:

SMD components have better electrical performance compared to THD components. This is because SMD components have shorter leads, resulting in less parasitic capacitance and inductance, leading to better signal integrity.

In summary, SMD components offer a more compact design, better electrical performance, and a faster assembly process, but at a higher cost. THD components, on the other hand, are larger in size, less expensive, and can handle higher power and voltage ratings. The choice between SMD and THD components depends on the specific requirements of the PCB design and the intended use of the electronic device.

6.What materials are commonly used to make PCBs?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

1. Copper: Copper is the most commonly used material for PCBs. It is used as the conductive layer for the circuit traces and pads.

2. FR4: FR4 is a type of fiberglass-reinforced epoxy laminate that is used as the base material for most PCBs. It provides good mechanical strength and insulation properties.

3. Solder mask: Solder mask is a layer of polymer that is applied over the copper traces to protect them from oxidation and to prevent solder bridges during assembly.

4. Silkscreen: Silkscreen is a layer of ink that is printed on top of the solder mask to provide component labels, reference designators, and other information.

5. Tin/lead or lead-free solder: Solder is used to attach components to the PCB and to create electrical connections between them.

6. Gold: Gold is used for plating the contact pads and vias on the PCB, as it provides good conductivity and corrosion resistance.

7. Silver: Silver is sometimes used as an alternative to gold for plating contact pads and vias, as it is cheaper but still provides good conductivity.

8. Nickel: Nickel is used as a barrier layer between the copper and gold or silver plating to prevent them from diffusing into each other.

9. Epoxy resin: Epoxy resin is used as an adhesive to bond the layers of the PCB together.

10. Ceramic: Ceramic materials are used for specialized PCBs that require high thermal conductivity and insulation properties, such as in high-power applications.

Tags:circuit card assembly manufacturing process,flexible pcb board,circuit card assembly vs pcb