16 soic pcb footprint

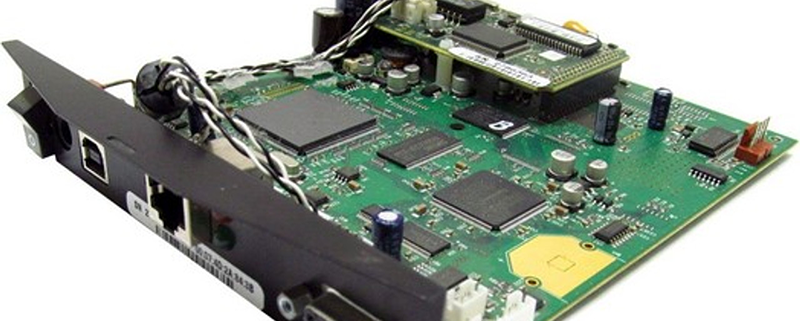

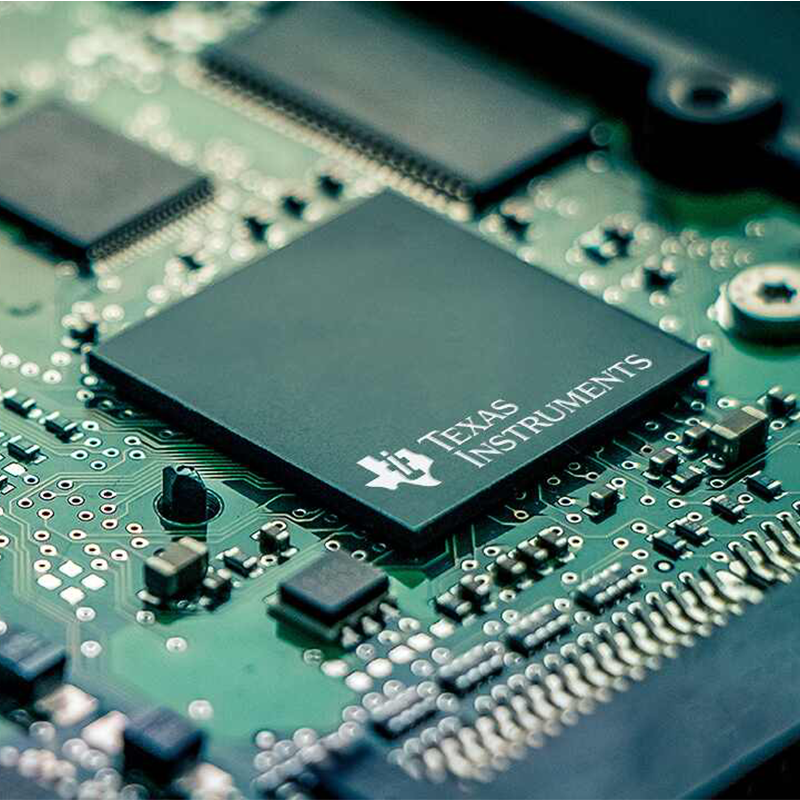

MTI is a manufacturer of high-precision printed circuit board (PCB).We specialize in the manufacture of high precision double-sided and multilayer printed circuit boards, We provide high quality products and faster service for high-tech companies.

We have a group of experienced staff and high-quality management team, set up a complete quality assurance system. Products include FR-4 PCB, Metal PCB and RFPCB (ceramic PCB, PTFE PCB), etc. Have rich experience in the production of thick copper PCB, RF PCB, high Tg PCB, HDI PCB.With ISO9001, ISO14001, TS16949, ISO 13485, RoHS certifications.

| Product name | 16 soic pcb footprint |

| Keyword | china rigid flex electronic pcba,10 layer pcb stack up,1.2mm pcb |

| Place of Origin | China |

| Board Thickness | 2~3.2mm |

| Applicable Industries | industrial control, etc. |

| Service | OEM/ODM manufacturing |

| Certificate | ISO-9001:2015, ISO-14001:2015,ISO-13485:2012.UL/CSA |

| Solder Mask Color | White |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Sales country | All over the world for example:Falkland Islands,Venezuela,Faroe Islands,Georgia,France,Niue,Netherlands,Malaysia |

One of our Hardware Design Services is small-batch manufacturing, which allows you to test your idea quickly and verify the functionality of the hardware design and PCB board.

We have rich experience engineer to create a layout using a software platform like Altium Designer. This layout shows you the exact appearance and placement of the components on your board.

Your deliverables are always ahead of schedule and of the highest quality.

FAQs Guide

2.Can a PCB have different levels of flexibility?

3.How does the type of PCB connection (wired or wireless) impact its design and features?

4.How does the type of laminate material used impact the PCB design?

5.How does the type of vias used affect the performance of a PCB?

6.What is the minimum distance required between components on a PCB?

7.What is the difference between single-sided and double-sided PCBs?

1.How does the type of solder mask used affect the PCB’s performance?

We have broad development space in domestic and foreign markets. 16 soic pcb footprints have great advantages in terms of price, quality, and delivery date.

The type of solder mask used can affect the PCB’s performance in several ways:

1. Insulation: Solder mask is used to insulate the copper traces on a PCB, preventing them from coming into contact with each other and causing a short circuit. The type of solder mask used can affect the level of insulation provided, which can impact the overall reliability and functionality of the PCB.

2. Solderability: Solder mask also plays a crucial role in the soldering process. The type of solder mask used can affect the surface tension and wetting properties of the solder, which can impact the quality of the solder joints and the overall reliability of the PCB.

3. Thermal resistance: Solder mask can also act as a thermal barrier, protecting the PCB from excessive heat. The type of solder mask used can affect the thermal resistance of the PCB, which can impact its ability to dissipate heat and its overall thermal performance.

4. Chemical resistance: Solder mask is also exposed to various chemicals during the PCB manufacturing process, such as flux and cleaning agents. The type of solder mask used can affect its resistance to these chemicals, which can impact the overall durability and reliability of the PCB.

5. Electrical properties: The type of solder mask used can also affect the electrical properties of the PCB, such as its dielectric constant and dissipation factor. These properties can impact the performance of high-frequency circuits and signal integrity.

Overall, the type of solder mask used can have a significant impact on the performance, reliability, and durability of a PCB. It is essential to carefully select the appropriate solder mask for a specific application to ensure optimal performance.

2.Can a PCB have different levels of flexibility?

We have a wide range of 16 soic pcb footprint customer groups and establishes long -term cooperative relationships with partners.

Yes, a PCB (printed circuit board) can have different levels of flexibility depending on its design and materials used. Some PCBs are rigid and cannot bend or flex at all, while others are designed to be flexible and can bend or twist to a certain degree. There are also PCBs that have a combination of rigid and flexible areas, known as flex-rigid PCBs. The level of flexibility in a PCB is determined by factors such as the type of substrate material, the thickness and number of layers, and the type of circuit design.

3.How does the type of PCB connection (wired or wireless) impact its design and features?

Our products & services cover a wide range of areas and meet the needs of different fields.

The type of PCB connection, whether wired or wireless, can have a significant impact on the design and features of the PCB. Some of the key ways in which the type of connection can impact the PCB design and features are:

1. Size and form factor: Wired PCBs typically require physical connectors and cables, which can add to the overall size and form factor of the PCB. On the other hand, wireless PCBs do not require physical connectors and cables, allowing for a smaller and more compact design.

2. Power consumption: Wired PCBs require a constant supply of power to function, whereas wireless PCBs can operate on battery power. This can impact the power consumption and battery life of the device, which in turn can affect the overall design and features of the PCB.

3. Flexibility and mobility: Wireless PCBs offer greater flexibility and mobility as they do not have physical connections that restrict movement. This can be advantageous in applications where the device needs to be moved or used in different locations.

4. Data transfer speed: Wired PCBs typically have faster data transfer speeds compared to wireless PCBs. This can impact the design and features of the PCB, as certain applications may require high-speed data transfer.

5. Cost: The type of connection can also impact the cost of the PCB. Wired PCBs may require additional components such as connectors and cables, which can add to the overall cost. Wireless PCBs, on the other hand, may require more advanced technology and components, making them more expensive.

6. Reliability: Wired PCBs are generally considered more reliable as they have a physical connection, which is less prone to interference or signal loss. Wireless PCBs, on the other hand, may be more susceptible to interference and signal loss, which can impact their reliability.

Overall, the type of PCB connection can significantly impact the design and features of the PCB, and it is important to carefully consider the specific requirements of the application when choosing between wired and wireless connections.

4.How does the type of laminate material used impact the PCB design?

As one of the top 16 soic pcb footprint manufacturers in China, we take this very seriously.

The type of laminate material used can impact the PCB design in several ways:

1. Electrical properties: Different laminate materials have different electrical properties, such as dielectric constant, loss tangent, and insulation resistance. These properties can affect the signal integrity and impedance of the PCB, which can impact the performance of the circuit.

2. Thermal properties: Some laminate materials have better thermal conductivity than others, which can affect the heat dissipation of the PCB. This is especially important for high-power applications where heat management is crucial.

3. Mechanical properties: The mechanical properties of the laminate material, such as stiffness and flexibility, can impact the overall durability and reliability of the PCB. This is important for applications where the PCB may be subjected to physical stress or vibration.

4. Cost: Different laminate materials have different costs, which can impact the overall cost of the PCB. Some materials may be more expensive but offer better performance, while others may be more cost-effective but have lower performance.

5. Manufacturing process: The type of laminate material used can also impact the manufacturing process of the PCB. Some materials may require specialized equipment or processes, which can affect the production time and cost.

6. Compatibility with components: Certain laminate materials may not be compatible with certain components, such as high-frequency components or components that require specific soldering temperatures. This can limit the design options and affect the functionality of the PCB.

Overall, the type of laminate material used can significantly impact the design, performance, and cost of a PCB. It is important to carefully consider the requirements of the circuit and choose a suitable laminate material to ensure optimal performance and reliability.

5.How does the type of vias used affect the performance of a PCB?

Being one of the top 16 soic pcb footprint manufacturers in China, We attach great importance to this detail.

The type of vias used can affect the performance of a PCB in several ways:

1. Signal Integrity: Vias can act as discontinuities in the signal path, causing reflections and signal degradation. The type of via used can impact the impedance and signal integrity of the PCB. For high-speed signals, it is important to use controlled impedance vias to maintain signal integrity.

2. Electrical Performance: The type of via used can also affect the electrical performance of the PCB. For example, through-hole vias have lower resistance and inductance compared to blind or buried vias, which can affect the power delivery and signal transmission on the PCB.

3. Thermal Performance: Vias can also play a role in the thermal performance of a PCB. Through-hole vias can act as thermal vias, allowing heat to dissipate from one layer to another. Blind and buried vias, on the other hand, can trap heat and affect the overall thermal management of the PCB.

4. Manufacturing Cost: The type of via used can also impact the cost of manufacturing the PCB. Blind and buried vias require more complex and expensive processes, while through-hole vias are relatively simpler and cheaper to manufacture.

5. PCB Size and Density: The type of via used can also affect the size and density of the PCB. Blind and buried vias take up less space on the surface of the PCB, allowing for higher density designs. This can be beneficial for smaller and more compact PCBs.

Overall, the type of vias used can have a significant impact on the performance, cost, and design of a PCB. It is important to carefully consider the type of vias needed for a specific application to ensure optimal performance and functionality of the PCB.

6.What is the minimum distance required between components on a PCB?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 16 soic pcb footprint products.

The minimum distance required between components on a PCB depends on various factors such as the type of components, their size, and the manufacturing process used. Generally, the minimum distance between components is determined by the manufacturer’s design rules and guidelines.

For surface mount components, the minimum distance between components is typically 0.2mm to 0.3mm. This distance is necessary to ensure that the solder paste does not bridge between the pads during the reflow process.

For through-hole components, the minimum distance between components is typically 1mm to 2mm. This distance is necessary to ensure that the components do not interfere with each other during the assembly process.

In high-speed and high-frequency applications, the minimum distance between components may need to be increased to avoid signal interference and crosstalk. In these cases, the manufacturer’s design rules and guidelines should be followed closely.

Overall, the minimum distance between components on a PCB should be determined based on the specific requirements of the design and the capabilities of the manufacturing process.

7.What is the difference between single-sided and double-sided PCBs?

Our mission is to provide customers with the best solutions for 16 soic pcb footprint.

Single-sided PCBs have copper traces and components on only one side of the board, while double-sided PCBs have copper traces and components on both sides of the board. This allows for more complex circuit designs and a higher density of components on a double-sided PCB. Single-sided PCBs are typically used for simpler circuits and are less expensive to manufacture, while double-sided PCBs are used for more complex circuits and are more expensive to manufacture.

Tags:3018 pcb , pcb boards , oem rigid flex electronic pcba , 1.6 mm pcb