Comparing Different PCB Manufacturing Techniques

Introduction to MTI PCB Manufacturing

MTI is a premier manufacturer specializing in PCB (Printed Circuit Board) assembly, known for our cutting-edge technology and high-quality production processes. In this article, we explore various PCB manufacturing techniques, comparing their features, advantages, and applications. This comprehensive comparison will help you understand the best options for your specific needs and why MTI is the preferred choice for PCB assembly.

Key PCB Manufacturing Techniques

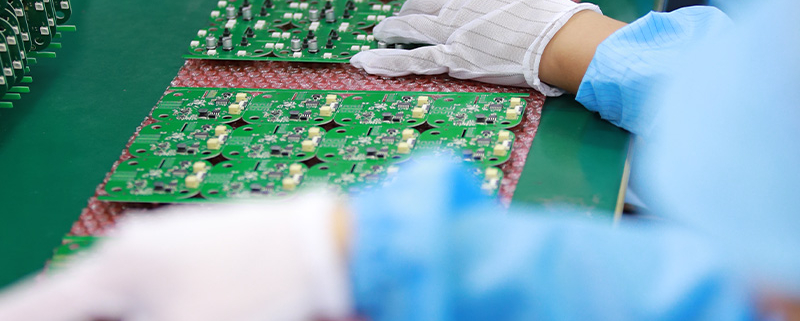

Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is one of the most widely used PCB manufacturing techniques. In this process, electronic components are mounted directly onto the surface of the PCB. MTI utilizes advanced SMT equipment to place components with high precision and speed.

- Advantages:

- High component density

- Improved performance and reliability

- Reduced size and weight of PCBs

- Automated assembly process, leading to faster production and lower costs

- Applications:

- Consumer electronics

- Telecommunications

- Automotive industry

- Medical devices

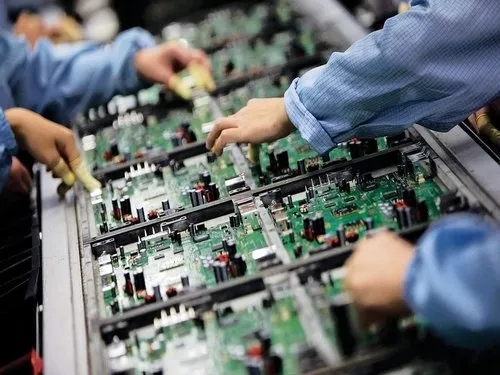

Through-Hole Technology (THT)

Through-Hole Technology (THT) involves inserting component leads through holes drilled into the PCB and soldering them in place. MTI employs precise drilling and soldering techniques to ensure robust and reliable connections.

- Advantages:

- Strong mechanical bonds, suitable for components subject to mechanical stress

- Higher power handling capacity

- Easier manual assembly and prototyping

- Applications:

- Industrial equipment

- Power supplies

- Aerospace and military applications

- High-reliability products

Hybrid Technology

Hybrid Technology combines both SMT and THT methods, leveraging the strengths of each technique to produce versatile and high-performance PCBs. MTI specializes in integrating these technologies to create complex and efficient assemblies.

- Advantages:

- Optimal balance between component density and mechanical strength

- Flexibility in design and component selection

- Enhanced performance for specialized applications

- Applications:

- Advanced communication systems

- Complex industrial control systems

- High-performance computing

- Custom electronic devices

Advanced PCB Manufacturing Techniques

Flexible PCB Manufacturing

Flexible PCBs, also known as flex circuits, are made from flexible plastic substrates, allowing the board to bend and fold. MTI’s flexible PCB manufacturing process ensures high durability and reliability.

- Advantages:

- Lightweight and space-saving

- High flexibility for dynamic applications

- Resistant to vibrations and mechanical stress

- Applications:

- Wearable electronics

- Medical devices

- Automotive and aerospace applications

- Consumer electronics

Rigid-Flex PCB Manufacturing

Rigid-Flex PCBs combine the benefits of both rigid and flexible PCBs, providing a hybrid solution for complex designs. MTI’s expertise in rigid-flex PCB manufacturing ensures high performance and reliability.

- Advantages:

- Combination of flexibility and rigidity in a single board

- Reduced connector and cable requirements

- Enhanced mechanical stability and durability

- Applications:

- Advanced medical devices

- Military and aerospace electronics

- High-end consumer electronics

- Telecommunications equipment

Benefits of Choosing MTI for PCB Manufacturing

State-of-the-Art Technology

MTI utilizes the latest technology and equipment in PCB manufacturing, ensuring high precision, speed, and quality. Our advanced facilities are equipped to handle a wide range of PCB manufacturing techniques, from SMT and THT to flexible and rigid-flex PCBs.

Customization and Flexibility

MTI offers customized PCB solutions tailored to meet the specific needs of our clients. Our flexible manufacturing processes allow us to accommodate various design requirements and production volumes, ensuring that we deliver the best possible solutions for your projects.

Quality and Reliability

At MTI, we prioritize quality and reliability in every step of the PCB manufacturing process. Our rigorous quality control measures and adherence to industry standards ensure that our PCBs meet the highest performance and durability standards.

Conclusion

MTI is dedicated to providing top-tier PCB manufacturing solutions through a variety of advanced techniques. Whether you need high-density SMT, robust THT, or specialized flexible and rigid-flex PCBs, MTI has the expertise and technology to deliver exceptional results. Choose MTI for your PCB assembly needs and experience the difference in quality, reliability, and performance.