High-Temperature Resistant PCB Manufacturing for Industrial Use

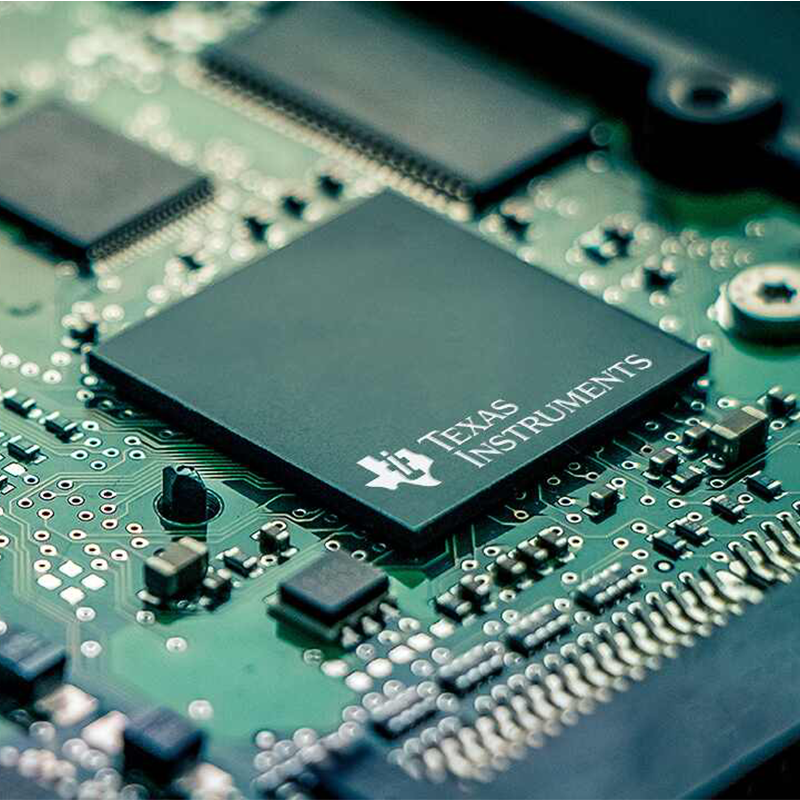

Introduction to MTI High-Temperature Resistant PCB

MTI is a leading PCB assembly manufacturer, renowned for our expertise in producing high-quality, high-temperature resistant PCBs designed for demanding industrial applications. Our advanced manufacturing processes and materials ensure that our PCBs can withstand extreme temperatures while maintaining excellent performance and reliability. In this article, we explore the features, benefits, and applications of MTI’s high-temperature resistant PCBs, demonstrating why they are the ideal choice for industrial use.

Importance of High-Temperature Resistant PCBs

Industrial Demands

Industrial environments often involve harsh conditions, including high temperatures, which can affect the performance and lifespan of electronic components. MTI’s high-temperature resistant PCBs are engineered to meet these challenging conditions, providing robust and reliable performance.

Material Durability

High-temperature resistant PCBs are made from materials that can withstand prolonged exposure to elevated temperatures without degrading. MTI uses advanced materials such as polyimide and ceramic substrates, which offer excellent thermal stability and durability, ensuring that our PCBs perform reliably in high-temperature environments.

Features of MTI High-Temperature Resistant PCBs

Advanced Material Selection

MTI’s high-temperature resistant PCBs are constructed using top-tier materials known for their thermal stability and durability. These include:

- Polyimide: Known for its high thermal resistance, polyimide is an ideal choice for PCBs exposed to extreme temperatures. It offers excellent mechanical and electrical properties, ensuring reliable performance.

- Ceramic Substrates: Ceramic materials provide superior thermal conductivity and stability, making them suitable for high-temperature applications. They are also highly resistant to chemical corrosion and mechanical wear.

Superior Thermal Management

Effective thermal management is crucial for high-temperature PCBs. MTI incorporates advanced thermal management techniques, such as thermal vias and heat sinks, to dissipate heat efficiently and prevent overheating. This ensures that the PCBs maintain optimal performance and reliability even under extreme conditions.

Robust Design and Construction

MTI’s high-temperature resistant PCBs are designed to withstand the mechanical stresses and vibrations commonly encountered in industrial environments. Our robust design and construction techniques ensure that the PCBs remain intact and function properly, even in the harshest conditions.

Benefits of MTI High-Temperature Resistant PCBs

Enhanced Reliability

Reliability is paramount in industrial applications, and MTI’s high-temperature resistant PCBs deliver exceptional performance. The use of high-quality materials and advanced manufacturing processes ensures that our PCBs can withstand extreme temperatures and maintain their functionality over long periods.

Extended Lifespan

MTI’s high-temperature resistant PCBs are designed for longevity. By using materials that do not degrade under high temperatures, we ensure that our PCBs have an extended lifespan, reducing the need for frequent replacements and minimizing downtime in industrial operations.

Versatility in Applications

Our high-temperature resistant PCBs are suitable for a wide range of industrial applications, including:

- Automotive: High-temperature PCBs are essential in automotive electronics, where they must endure the heat generated by engines and other components.

- Aerospace: Aerospace applications require PCBs that can withstand extreme temperatures and harsh environmental conditions.

- Oil and Gas: Equipment used in the oil and gas industry often operates in high-temperature environments, necessitating the use of robust and reliable PCBs.

- Industrial Machinery: High-temperature resistant PCBs are crucial for the reliable operation of industrial machinery and equipment.

Why Choose MTI for High-Temperature Resistant PCBs?

Expertise and Experience

MTI has extensive experience and expertise in manufacturing high-temperature resistant PCBs. Our team of skilled engineers and technicians is dedicated to delivering top-quality products that meet the stringent demands of industrial applications.

State-of-the-Art Facilities

Our state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, allowing us to produce high-temperature resistant PCBs with precision and efficiency. We adhere to strict quality control standards to ensure that every PCB meets our high-performance criteria.

Customized Solutions

MTI offers customized PCB solutions tailored to the specific needs of our clients. Whether you require unique design features or specific material requirements, we work closely with you to deliver PCBs that perfectly match your industrial application needs.

Conclusion

MTI’s high-temperature resistant PCBs are the ideal choice for industrial applications that demand durability, reliability, and superior performance. Our commitment to using advanced materials and innovative manufacturing processes ensures that our PCBs can withstand extreme temperatures and harsh conditions. Choose MTI for your high-temperature PCB needs and benefit from our expertise, state-of-the-art facilities, and customized solutions designed to meet the most demanding industrial requirements.

Tags: PCB Manufacturer,PCB service,PCB Design & engineering,PCB Manufacturing,PCB Assemblies