The Ultimate PCB and Soldering Guide: From Basics to Advanced Techniques by MTI

When it comes to printed circuit boards (PCBs) and soldering, MTI stands out as a leading PCB assembly manufacturer. With a commitment to excellence and innovation, MTI offers a comprehensive range of services, from design and R&D to manufacturing and OEM/ODM solutions. This guide will take you through the essentials of PCB and soldering, helping you understand the processes and the expertise that MTI brings to the table.

Introduction to PCBs and Soldering

PCBs are the backbone of electronic devices, providing the physical foundation and electrical connections that make technology work. Soldering is the process of joining components to the PCB, ensuring reliable and stable connections. Mastering these skills is crucial for anyone involved in electronics.

MTI: Your Trusted PCB Assembly Manufacturer

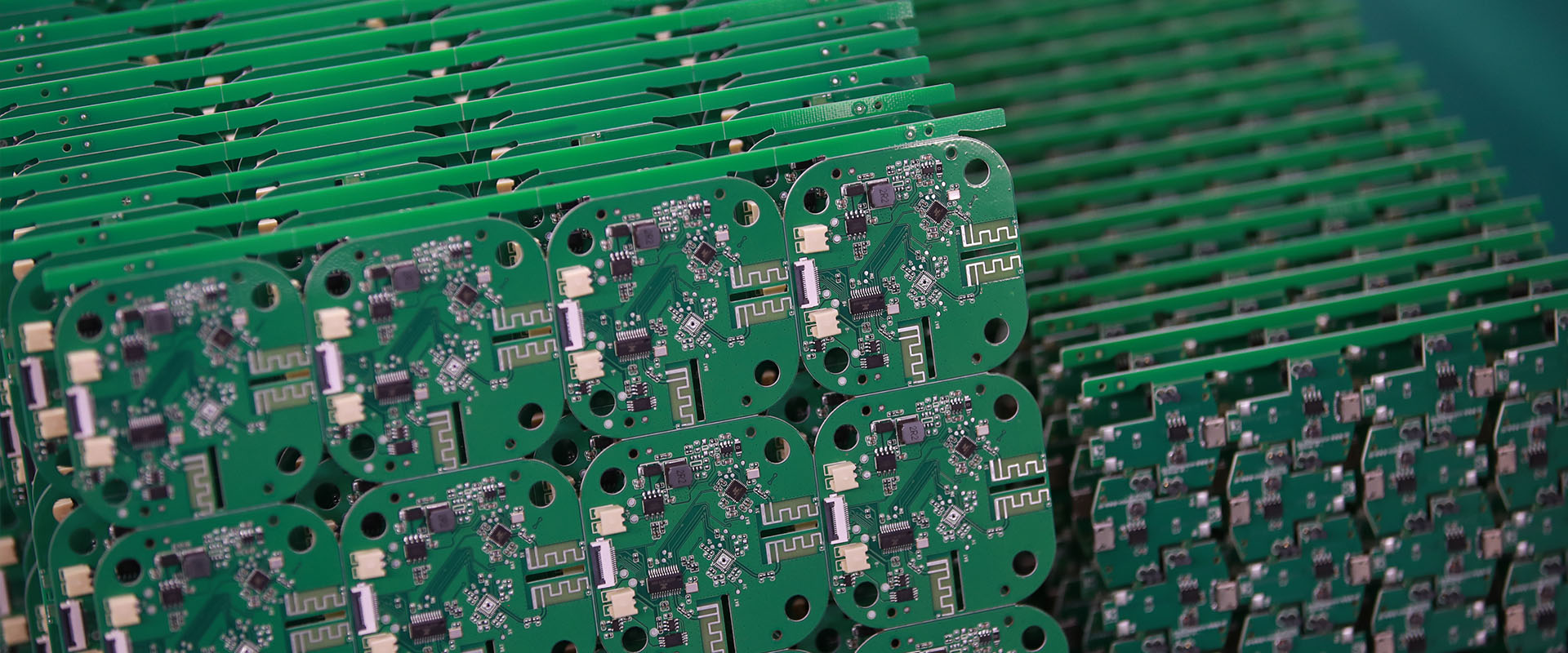

At MTI, we pride ourselves on being a top-tier PCB assembly manufacturer. Our state-of-the-art facilities and skilled workforce enable us to deliver high-quality PCBs tailored to your specific needs. Whether you require small-scale prototypes or large-scale production, we have the capabilities to meet your demands.

Comprehensive Manufacturing Services

MTI offers a complete suite of manufacturing services. Our advanced manufacturing processes ensure precision and efficiency, resulting in PCBs that meet the highest standards of quality. We utilize cutting-edge technology to optimize production and minimize errors, ensuring that your products are built to last.

OEM/ODM Solutions

As an experienced OEM/ODM provider, MTI offers customized solutions that cater to your unique requirements. We work closely with you to develop products that align with your vision and specifications. Our flexible approach allows us to adapt to different industries and applications, providing you with tailored solutions that enhance your product offerings.

Expert R&D and Design Services

Research and development (R&D) are at the heart of innovation. MTI’s dedicated R&D team is constantly exploring new technologies and methodologies to improve our services. Our design experts collaborate with you to create PCBs that meet your functional and aesthetic requirements. From concept to completion, we ensure that every detail is meticulously planned and executed.

Soldering Techniques: From Basics to Advanced

Soldering is a critical skill in PCB assembly. Here’s a breakdown of the essential techniques:

1. Basic Soldering: Understanding the fundamentals of soldering, including the types of solder and flux, is essential. Properly heating the solder joint and applying the right amount of solder are key to creating reliable connections.

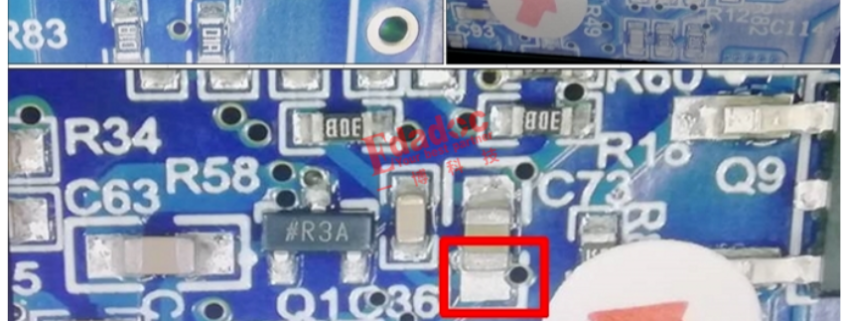

2. Surface Mount Technology (SMT): SMT is widely used in modern PCB assembly. It involves placing components directly onto the PCB surface and soldering them in place. This technique allows for more compact and efficient designs.

3. Through-Hole Soldering: This traditional method involves inserting component leads through holes in the PCB and soldering them on the opposite side. It is often used for components that require a stronger mechanical bond.

4. Reflow Soldering: Used primarily for SMT, reflow soldering involves applying solder paste to the PCB, placing components, and then heating the assembly in a reflow oven. The solder melts and forms solid connections as it cools.

5. Wave Soldering: Ideal for through-hole components, wave soldering involves passing the PCB over a wave of molten solder. This method is efficient for mass production.

Conclusion

MTI’s expertise in PCB assembly and soldering ensures that you receive top-quality products tailored to your needs. Our comprehensive services, including manufacturing, OEM/ODM, R&D, and design, make us your go-to partner for all your PCB requirements. Trust MTI to deliver excellence and innovation in every project.

Explore our services today and discover how MTI can elevate your electronic products to new heights.

Tags: PCB Bog,SCHEMATIC DESIGN,PCB LAYOUT,FIRMWARE DEVELOPMENT,SMT,PCB TPH Assembly,Box Build Assembly,NPI PCBA PROTOTYPE,