What do you need to know about PCBA Assembly?

What is PCBA Assembly?

PCBA assembly (Printed Circuit Board Assembly) is the process of assembling electronic components onto a printed circuit board (PCB). This includes soldering of surface mount and through-hole components, testing the functionality of the board, and applying any necessary firmware or software. The assembled PCB is then ready for use in a wide range of electronic devices, from smartphones and computers to industrial equipment and automotive systems. The PCBA assembly process requires specialized equipment and expertise to ensure that the components are accurately and securely placed and that the final product functions as intended. MTI (Micro Tech Industries) is a leading company in the field of PCBA assembly, offering high-quality services to a diverse range of industries such as consumer electronics, medical devices, automotive, and more. In this article, we will discuss the key aspects of PCBA assembly, including the importance of working with a reputable company like MTI, the Bill of Materials (BOM), component procurement and inspection, types of PCB, surface mount technology (SMT), soldering techniques, quality control tests, and final assembly and packaging.

The Importance of Working with MTI:

MTI is a reputable company that specializes in PCBA assembly. Partnering with MTI ensures that your PCBs are assembled using high-quality materials, advanced technology, and with the expertise of experienced professionals. They offer a range of services including PCB design, component sourcing, assembly, and testing to ensure that the final product meets your specifications and industry standards.

Knowledge of PCBA assembly

The PCBA assembly process involves several stages, each of which plays a crucial role in the final product’s quality and functionality. Let’s take a closer look at them:

1. Bill of Materials (BOM):

The BOM is a comprehensive list of all the components and materials required for the PCBA assembly process. It includes details such as part numbers, quantities, and reference designators. A detailed BOM helps the assembly team to source the necessary components and ensures that the final product meets the required specifications.

2. Component Procurement and Inspection:

Procuring components for PCBA assembly can be a time-consuming and complex process. This is why it is crucial to work with a reputable company like MTI, who has established relationships with trusted suppliers. Additionally, thorough inspection of the components is carried out to ensure they meet the required quality standards and are suitable for the assembly process.

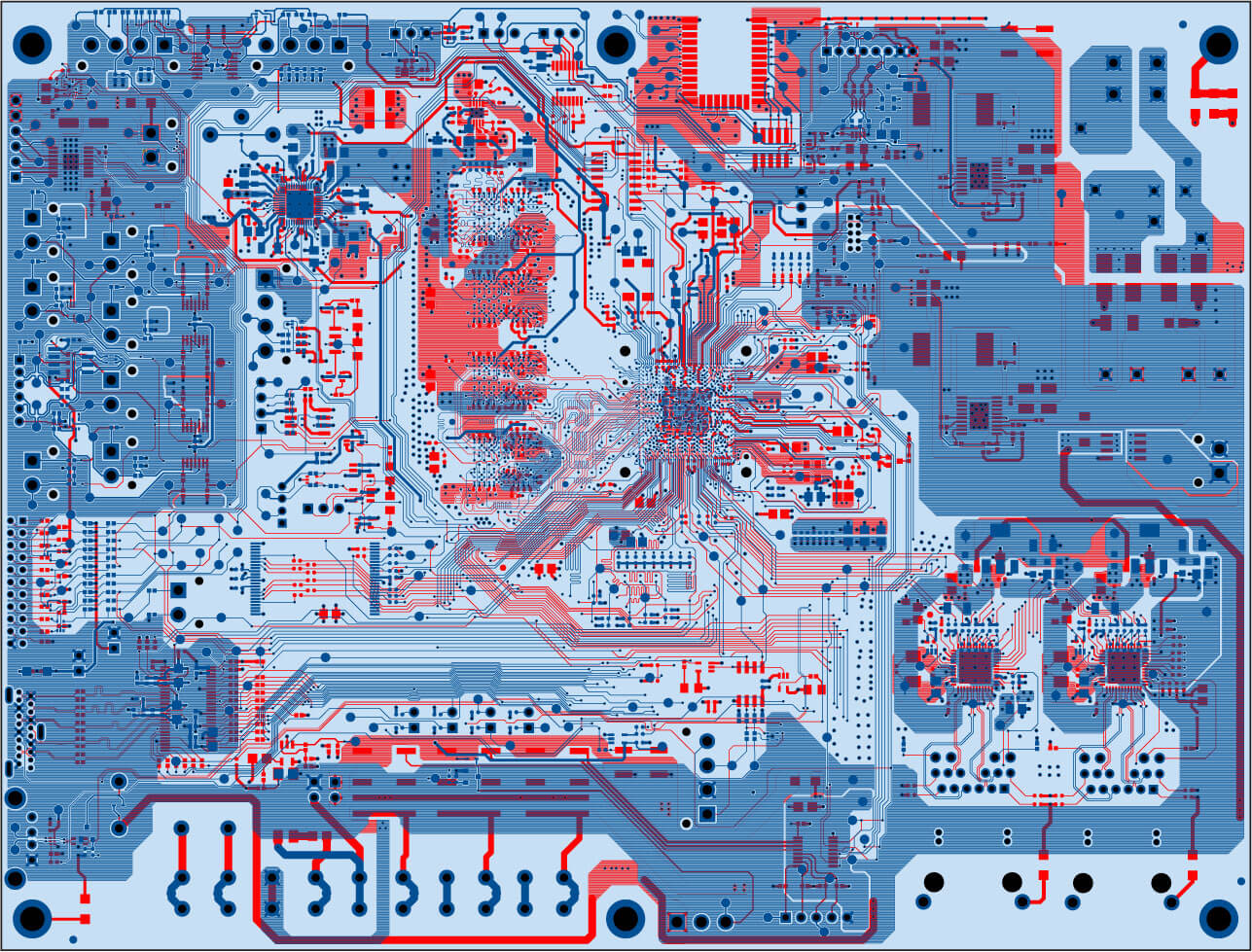

3. Types of PCB:

There are two types of PCB – through-hole and surface mount. Through-hole PCBs have components with leads that are inserted into pre-drilled holes on the PCB and soldered on the opposite side. On the other hand, surface mount PCBs have components with metal tabs or short leads that are soldered directly onto the surface of the PCB. SMT offers a more efficient and compact design, making it the preferred method for PCB assembly.

4. Soldering Techniques:

Once the components are placed onto the PCB, the next step is soldering. Reflow soldering and wave soldering are the two commonly used techniques. Reflow soldering is used for surface mount components and involves melting solder paste to create a strong bond between the components and PCB. Wave soldering, on the other hand, is used for through-hole components and involves passing the PCB over a wave of molten solder.

5. Quality Control Tests:

To ensure the functionality and reliability of the assembled PCB, quality control tests are carried out. Automated Optical Inspection (AOI) is a visual inspection process that uses cameras and software to detect any defects in the components or soldering. Afterwards, functional tests such as In-Circuit Test (ICT) and Burn-In Test are performed to ensure the circuit is functioning as expected.

6. Assembly and Packaging:

Upon successful completion of the quality control tests, the final step is assembly and packaging. This involves adding any final components such as connectors and cables and then packaging the PCB in a protective casing. The packaging ensures that the PCB is protected during transportation and storage.

Conclusion:

In conclusion, PCBA assembly is a crucial process in the production of electronic devices. Working with a reputable company like MTI, paying attention to the BOM, thorough component procurement and inspection, using the appropriate PCB, soldering techniques, and conducting quality control tests, are all vital aspects of a successful PCBA assembly. By understanding these key elements, you can ensure that your PCB is assembled correctly, efficiently, and meets the required quality standards.

Tag: PCB manufacturing, PCB Layout