Why Are Motor Control Solutions Essential in PCB Design?

MTI, a leading PCB assembly manufacturer, specializes in delivering innovative motor control solutions that are essential for efficient and reliable electronic systems. In today’s complex and fast-paced industries, motor control systems must provide precision, energy efficiency, and adaptability to meet the varying demands of applications such as automation, robotics, and consumer electronics. Proper motor control solutions in PCB design ensure that motors operate smoothly, reduce energy consumption, and enhance the overall performance of electronic devices. MTI’s motor control solutions integrate advanced technologies, such as pulse-width modulation (PWM), closed-loop control, and smart power management, allowing for highly precise control over motor speed, direction, and torque. These innovations are critical in improving the efficiency and lifespan of motors while reducing the risk of overheating or malfunction.

How Does MTI’s Motor Control Solutions Enhance PCB Efficiency?

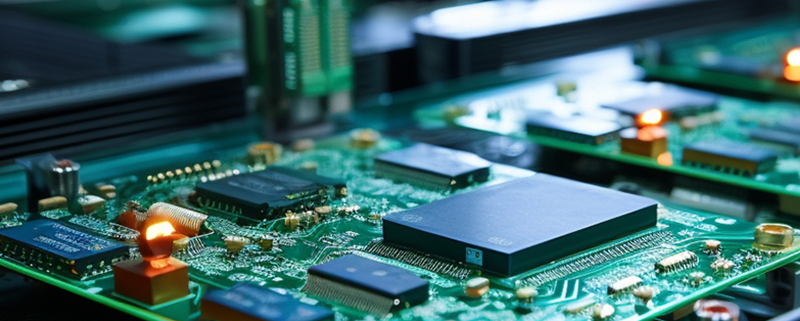

MTI’s motor control solutions are designed to enhance the overall efficiency of printed circuit boards by integrating cutting-edge technologies that optimize motor performance. One key feature of MTI’s motor control systems is advanced pulse-width modulation (PWM), which allows for precise control of motor speed and torque while minimizing energy loss. MTI also utilizes closed-loop control systems, which provide real-time feedback, ensuring that the motor responds accurately to changes in load or operational conditions. This results in smoother operation and longer motor life. Additionally, MTI’s PCBs are equipped with intelligent power management features, which automatically adjust energy consumption based on the motor’s demand, further improving efficiency and reducing heat generation. These features ensure that MTI’s motor control solutions offer enhanced performance while maintaining energy efficiency, making them ideal for a wide range of industrial and consumer applications.

Features and Functions of MTI’s Motor Control Solutions in PCB Design

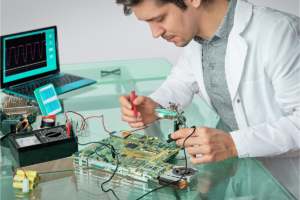

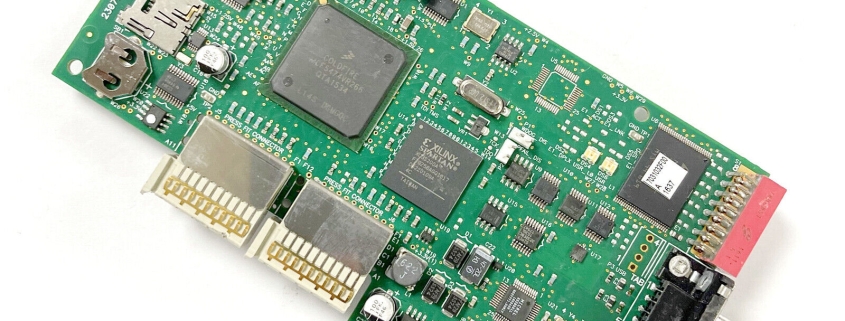

MTI’s motor control solutions in PCB design offer a range of advanced features that provide precise, reliable, and efficient motor management. One of the core features is the integration of smart controllers, which allow for real-time adjustments and monitoring of motor functions, ensuring optimal performance even under varying loads. The use of high-efficiency PWM controllers enables the precise modulation of motor speeds, helping to reduce power loss and maintain stable operation. MTI’s motor control PCBs also include overload protection and thermal management systems to safeguard the motor and the PCB from overheating or electrical faults, enhancing the overall durability and lifespan of the product. Moreover, the compact design and customizable control algorithms allow MTI’s solutions to be tailored to specific motor applications, ensuring flexibility across various industries. These features make MTI’s motor control solutions a robust and efficient choice for modern PCB designs, enhancing both performance and reliability.

Why Choose MTI for Innovative Motor Control PCB Solutions?

Choosing MTI for motor control PCB solutions means benefiting from their years of expertise and dedication to delivering high-performance and reliable products. MTI leverages advanced design tools and manufacturing technologies to develop motor control systems that offer precision, efficiency, and adaptability for a wide range of applications. Their motor control PCBs are tailored to handle diverse motor types, from simple DC motors to more complex stepper and brushless motors, ensuring that every solution is customized for optimal performance. Additionally, MTI is committed to sustainability, designing energy-efficient systems that reduce power consumption and extend the lifespan of motors. The company’s focus on quality and innovation ensures that clients receive PCB solutions that not only meet but exceed the demands of today’s rapidly evolving industries.

Conclusión

MTI’s innovative motor control solutions in PCB design offer advanced features that provide precise, efficient, and reliable motor management for various industries. With technologies like pulse-width modulation, closed-loop control, and smart power management, MTI ensures that its PCBs deliver high performance while reducing energy consumption and extending motor life. Their commitment to quality and customizability makes MTI a leading choice for businesses seeking advanced motor control solutions in PCB design.