Reducing Lead Times to Lower PCB Manufacturing Cost

MTI, a leading PCB assembly manufacturer, is committed to delivering high-quality printed circuit boards (PCBs) efficiently and cost-effectively. One critical factor in achieving this goal is reducing lead times in PCB manufacturing. This article explores how MTI optimizes lead times to lower manufacturing costs, highlighting the strategies, benefits, and impact on overall production efficiency.

Introduction to Lead Times in PCB Manufacturing

Importance of Lead Times

Definition and Overview

Lead time in PCB manufacturing refers to the total time taken from the initial order placement to the final delivery of the product. It encompasses various stages, including design, prototyping, production, and testing.

Impact on Costs

Long lead times can increase manufacturing costs due to extended labor, operational expenses, and potential delays in project timelines. Reducing lead times is crucial for improving cost efficiency and meeting market demands promptly.

Strategies for Reducing Lead Times at MTI

Streamlined Design Processes

Early Design Review

MTI conducts early design reviews to identify and resolve potential issues before they progress to the manufacturing stage. This proactive approach minimizes rework and reduces the time spent on design iterations.

Design for Manufacturability (DFM)

Incorporating DFM principles ensures that the PCB design is optimized for efficient manufacturing. This strategy reduces complexities, enhances production speed, and minimizes errors.

Advanced Prototyping Techniques

Rapid Prototyping

MTI utilizes rapid prototyping techniques to accelerate the development of PCB prototypes. By employing advanced tools and technologies, we can quickly produce and test prototypes, shortening the overall development cycle.

In-House Prototyping Capabilities

Having in-house prototyping capabilities allows MTI to control the entire process, reducing dependency on external suppliers and eliminating associated delays.

Efficient Production Processes

Automation and Robotics

Integrating automation and robotics in production processes enhances precision and speed. Automated systems streamline tasks such as component placement, soldering, and inspection, significantly reducing lead times.

Just-In-Time (JIT) Manufacturing

MTI employs JIT manufacturing principles to minimize inventory costs and ensure timely production. By synchronizing production schedules with demand, we reduce the waiting time for materials and components.

Optimized Supply Chain Management

Strong Supplier Relationships

MTI maintains strong relationships with reliable suppliers to ensure a steady and timely supply of materials and components. This collaboration minimizes delays and disruptions in the supply chain.

Real-Time Inventory Management

Implementing real-time inventory management systems allows us to monitor stock levels, track orders, and anticipate material requirements accurately. This system helps prevent shortages and reduces lead times.

Quality Control and Testing

Automated Testing

Automated testing processes, such as Automated Optical Inspection (AOI) and In-Circuit Testing (ICT), speed up the quality assurance phase. These technologies ensure that PCBs meet stringent quality standards without manual intervention delays.

Continuous Improvement

MTI is committed to continuous improvement, regularly reviewing and refining our processes to enhance efficiency and reduce lead times further. This commitment ensures that we remain competitive and responsive to market needs.

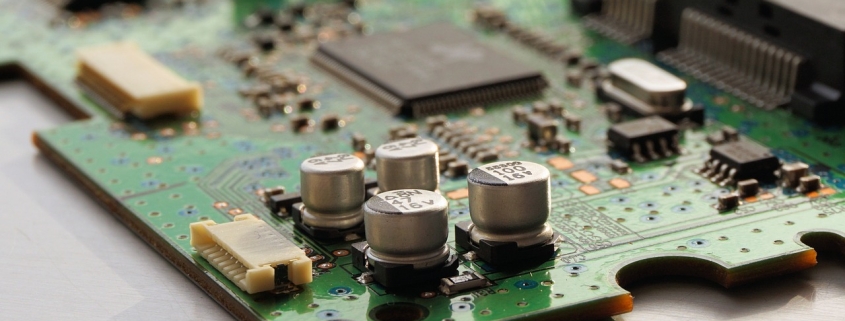

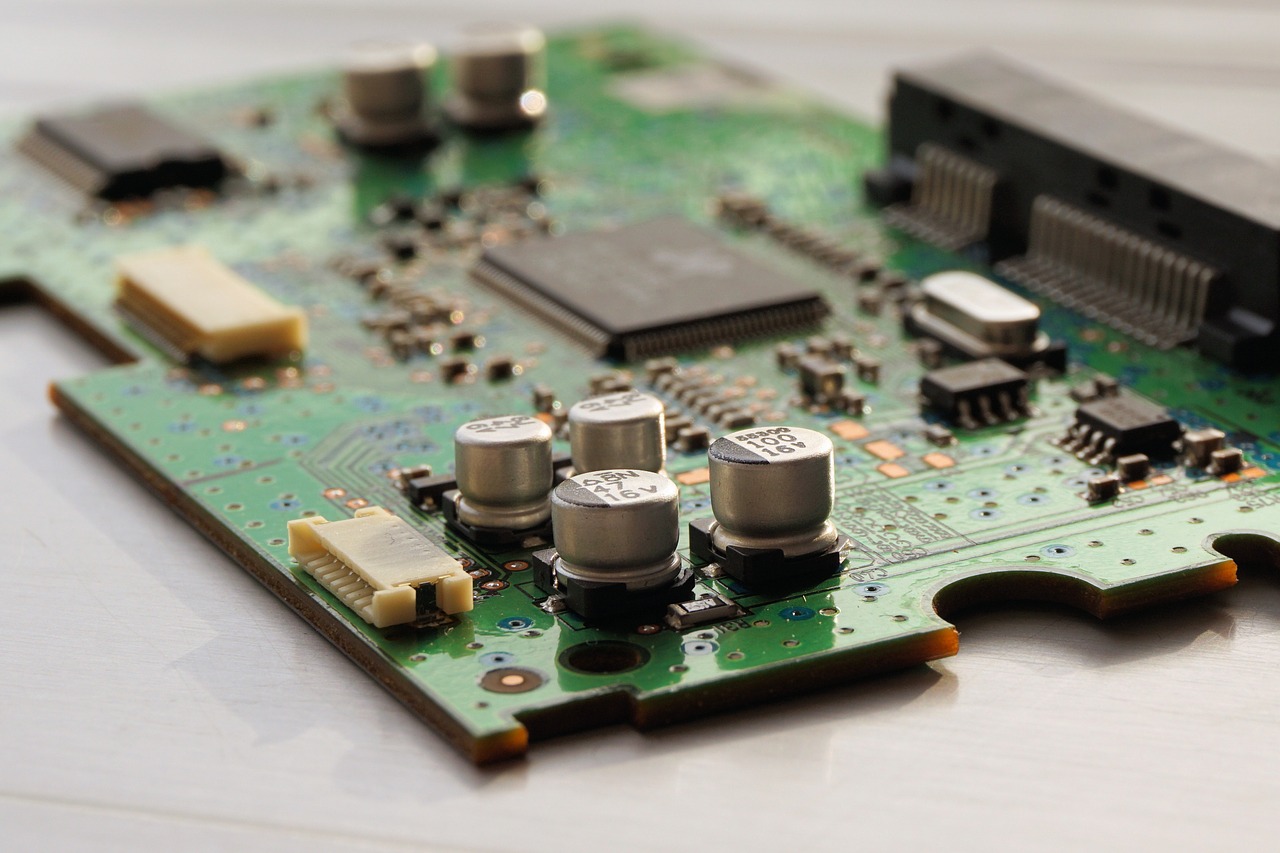

PCB Assembly

Benefits of Reducing Lead Times

Cost Reduction

Lower Labor Costs

Shorter lead times reduce the amount of labor required for each project, lowering overall labor costs. Efficient processes also reduce overtime and associated expenses.

Reduced Operational Costs

Optimizing lead times minimizes the operational costs associated with extended production cycles, such as energy consumption, equipment wear and tear, and facility overheads.

Enhanced Competitiveness

Faster Time-to-Market

Reducing lead times allows MTI to deliver products to market faster, giving our clients a competitive edge. Quick turnaround times enable businesses to capitalize on market opportunities promptly.

Increased Customer Satisfaction

Timely delivery of high-quality PCBs enhances customer satisfaction and builds trust. Satisfied customers are more likely to return for future projects and recommend MTI to others.

Improved Production Efficiency

Higher Throughput

Efficient processes and reduced lead times increase the throughput of our manufacturing facilities. This improvement allows MTI to handle more projects simultaneously, maximizing production capacity.

Flexibility and Adaptability

Shorter lead times provide greater flexibility in responding to changes in customer requirements or market conditions. MTI can adapt quickly to new demands, ensuring continuous alignment with client needs.

MTI’s Commitment to Reducing Lead Times

Investment in Technology

Cutting-Edge Equipment

MTI invests in state-of-the-art equipment and technologies to streamline production processes and reduce lead times. Our advanced machinery ensures precision, speed, and reliability in PCB manufacturing.

Research and Development

Our dedicated R&D team continuously explores new methodologies and technologies to improve manufacturing efficiency. This focus on innovation drives our ability to reduce lead times and enhance cost-effectiveness.

Skilled Workforce

Training and Development

MTI prioritizes the training and development of our workforce, ensuring that our team is skilled in the latest manufacturing techniques and technologies. A knowledgeable team is crucial for maintaining efficient operations and reducing lead times.

Collaborative Culture

We foster a collaborative culture where employees work together to identify and implement process improvements. This collective effort enhances our ability to reduce lead times and deliver high-quality products.

Conclusion

Reducing lead times is a critical factor in lowering PCB manufacturing costs and enhancing overall production efficiency. MTI employs a comprehensive approach that includes streamlined design processes, advanced prototyping, efficient production methods, optimized supply chain management, and rigorous quality control. By continuously investing in technology and our skilled workforce, MTI remains committed to delivering high-quality PCBs with reduced lead times, providing our clients with cost-effective solutions and a competitive advantage. Trust MTI, a leading PCB assembly manufacturer, to meet your PCB needs with efficiency and excellence.