What Are the Key Trends in PCB Miniaturization?

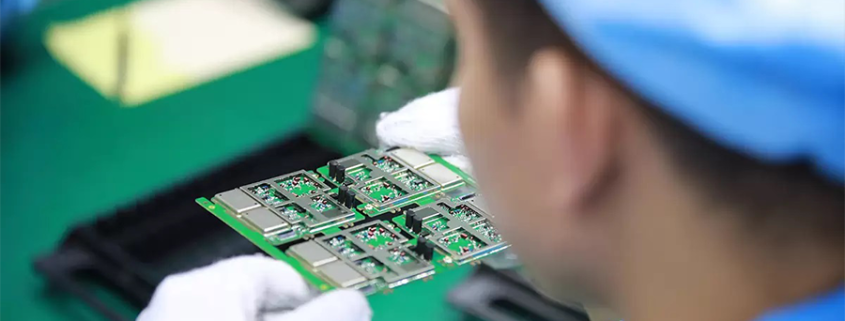

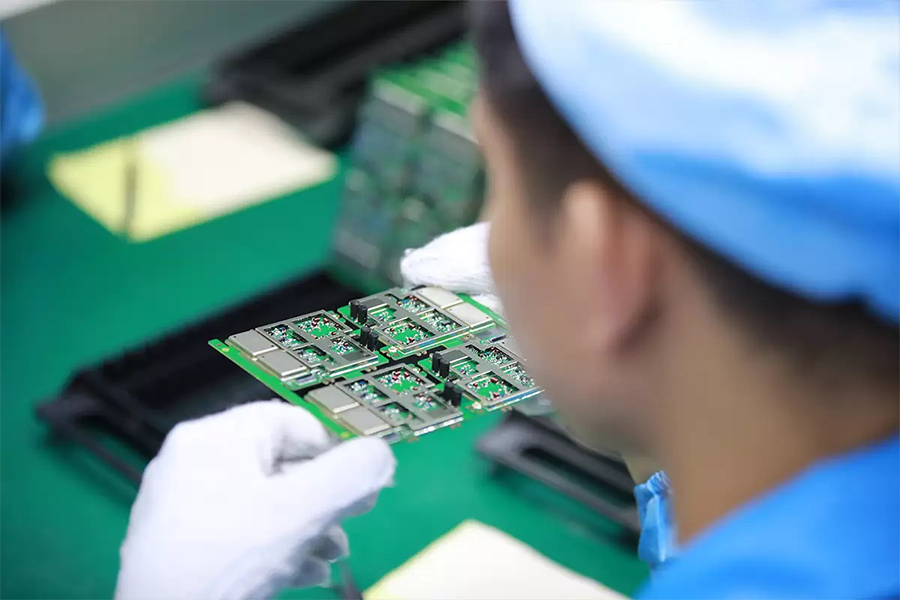

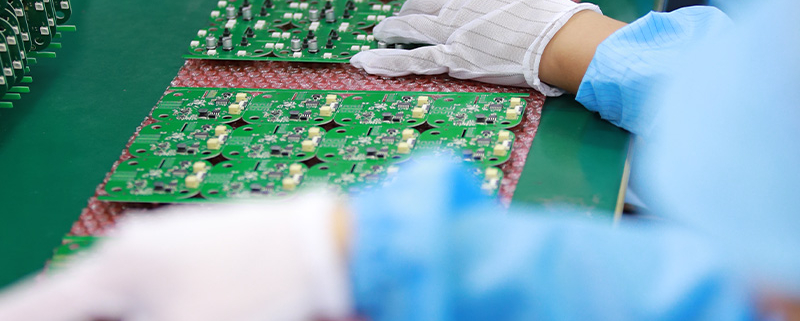

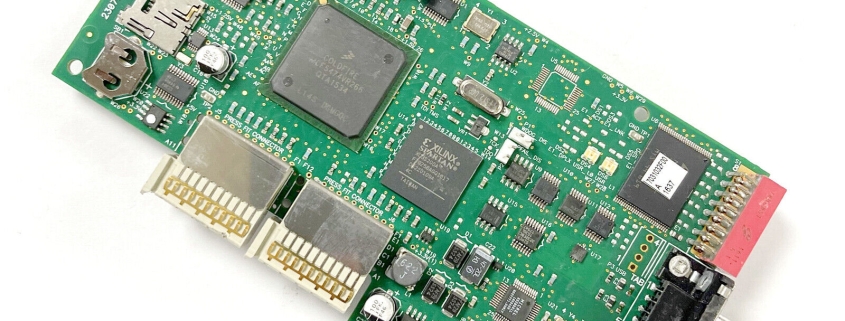

One of the most significant trends in PCB design is the drive toward miniaturization. As electronic devices become more compact, the demand for smaller, yet highly efficient PCBs continues to grow. MTI, a leading PCB assembly manufacturer, has witnessed an increased focus on designing PCBs that can support complex functionality in a reduced form factor. With advances in manufacturing and R&D, MTI is able to produce multi-layered boards with fine-pitch components that are essential for devices like smartphones, wearables, and IoT gadgets. This trend not only improves cost performance but also opens new opportunities for product innovation in industries such as consumer electronics and medical devices.

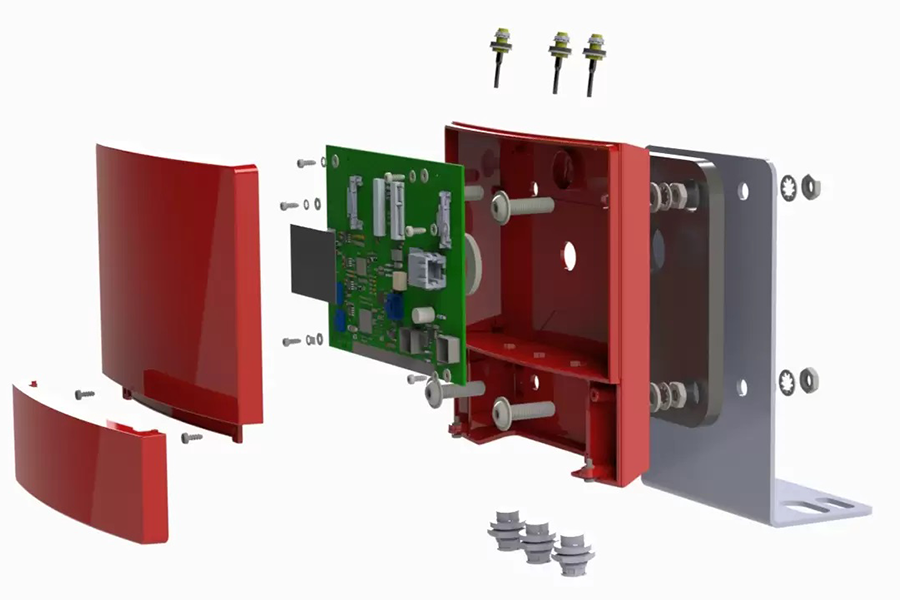

Miniaturization also involves the use of advanced materials and technologies, such as high-density interconnect (HDI) PCBs and flexible circuits, which allow for more components to be packed into a smaller space. MTI leverages its expertise in OEM/ODM services to provide customized PCB designs that align with the latest miniaturization trends, ensuring that clients can stay competitive in their respective markets.

How Are High-Speed PCBs Shaping the Future of Technology?

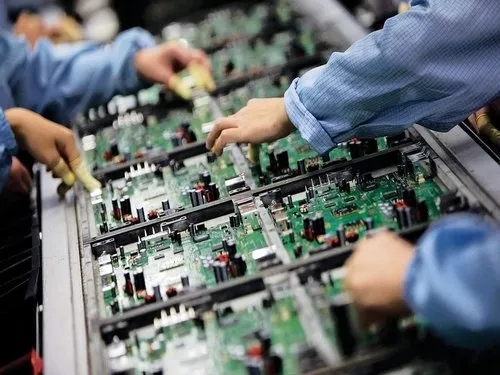

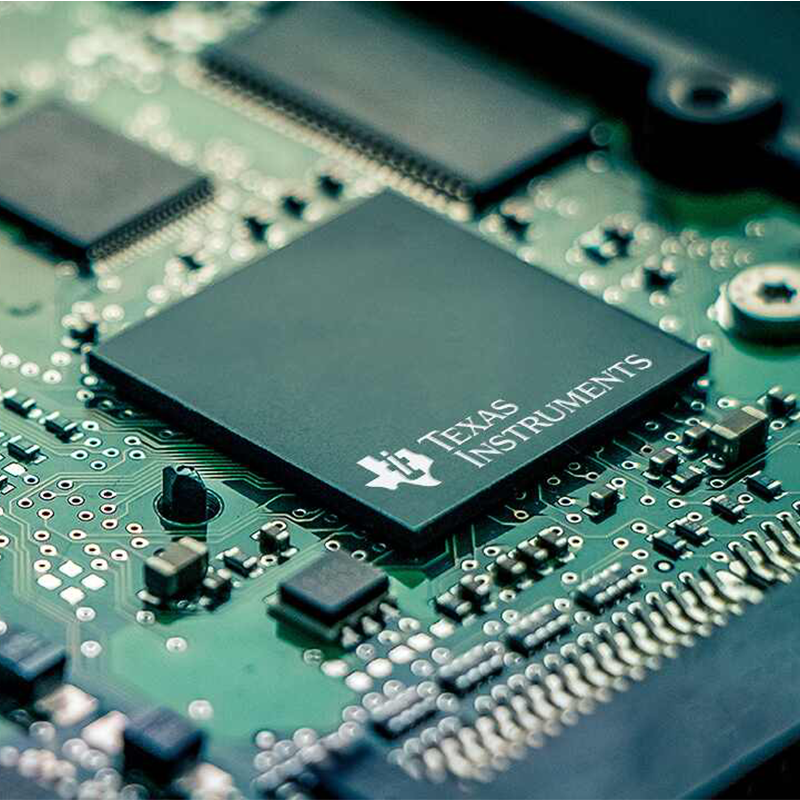

Another notable trend in PCB design is the rise of high-speed PCBs, which are essential for handling the increased data transmission rates required by modern devices. As technologies like 5G, AI, and autonomous systems evolve, the need for PCBs that can support high-frequency signals without signal loss or interference has become critical. MTI’s advanced PCB assembly capabilities allow for the manufacturing of high-speed PCBs that meet stringent signal integrity requirements, making them suitable for applications in telecommunications, automotive, and computing industries.

High-speed PCB design focuses on reducing electromagnetic interference (EMI) and cross-talk between signals, which can degrade performance in data-intensive applications. MTI’s R&D and design teams employ innovative techniques such as controlled impedance routing, differential pair routing, and the use of high-frequency materials to ensure that their PCBs can handle the demands of next-generation technologies. This trend not only enhances the efficiency of electronic devices but also offers an advantage for businesses looking to lead in the development of cutting-edge products.

The Advantages of Following PCB Design Trends with MTI

Staying up-to-date with the latest trends in PCB design offers a significant advantage for businesses looking to enhance their product offerings. MTI’s expertise in both miniaturization and high-speed PCBs ensures that clients receive high-performance, cost-effective solutions tailored to their specific needs. By partnering with MTI, businesses gain access to the latest design innovations, improving their product’s market competitiveness.

For OEM/ODM partners, distributors, and agents, MTI’s focus on trend-driven design and manufacturing ensures that they are always ahead of the curve. With MTI’s cutting-edge technology and commitment to quality, customers benefit from PCBs that not only meet current industry standards but are also future-proofed to support emerging technological advancements.

Conclusion

The latest trends in PCB design, including miniaturization and high-speed PCBs, are shaping the future of electronics manufacturing. MTI, as a leader in PCB assembly, is at the forefront of these trends, offering innovative design and manufacturing solutions. By embracing these advancements, MTI provides clients with high-quality, trend-driven PCBs that improve performance and ensure cost-effective production, making them a reliable partner in the rapidly evolving tech landscape.

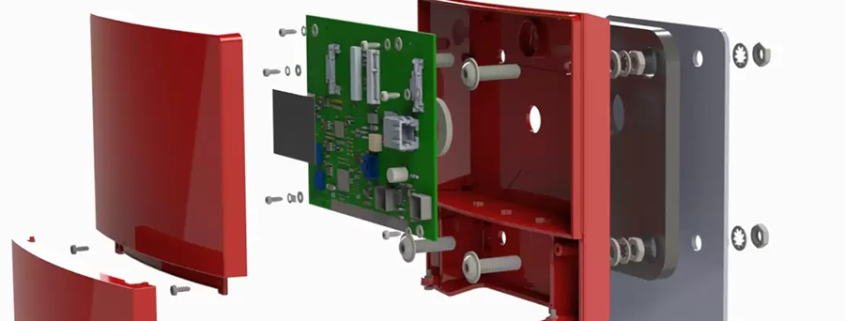

Box Build

Box Build